Modern sewerage systems demand a new generation of pipework and components that focus on installation, sustainability and compliance.

JDP provides ULTRA3 sewer drainage system, sized from 110mm to 630mm, that offers a dual-purpose system for underground drainage.

Manufactured from PVC-U and certified (Kitemarked) to BS EN 13476-2 as a SN8-rated smooth-wall structured layer pipe, ULTRA3 can be used in both house drainage (100/110mm & 150/160mm) and adoptable sewers (150/160mm - 600/630mm) compliant with water authority requirements.

With a full combination of fittings ULTRA3 is the ultimate underground sewer drainage system.

Download ULTRA3 Product Guide Buy OnlineULTRA3 Underground Drainage System

Dimensions

| Nominal Size (mm) | Lengths | OD (mm) | Wall Thickness (mm) | ID (mm) | Weight / m (kg) |

|---|---|---|---|---|---|

| 100/110 | 3m & 6m | 110 | 3.20 | 103.60 | 1.33 |

| 150/160 | 3m & 6m | 160 | 4.70 | 150.60 | 2.94 |

| 185/200 | 3m | 200 | 5.90 | 188.20 | 4.75 |

| 225/250 | 3m | 250 | 7.30 | 235.4 | 7.14 |

| 300/315 | 3m | 315 | 9.20 | 296.60 | 11.33 |

| 375/400 | 3m | 400 | 11.70 | 376.60 | 19.43 |

| 475/500 | 3m | 500 | 14.60 | 470.80 | 30.34 |

| 600/630 | 3m | 630 | 18.4 | 593.20 | 45.78 |

Features & Benefits

Installation & Maintenance

- An integral seal quickens installation, increases seal quality and reduces delays and air test failure rates

- ULTRA3 provides a direct connection to PPIC and AXEDO® chambers without the use of adaptors

- Inherent resistance to potential damage from cleaning and maintenance

- Tested and exceeds the requirements of WIS 4-35-01 exceeding a jetting resistance of 4000 psi (275 bar)

Sustainability

- Pipework manufactured with at least 40% recycled material to EN 13476-2 with an intermediary layer of recycled PVC, with virgin PVC inner and outer layers

- Makes 100/110mm and 150/160mm pipework 20-25% lighter than EN 1401 pipework

- Provides safe and easier handling on site and a reduced carbon footprint compared to alternative systems

Compliance

- ULTRA3 SN8 pipework certified (Kitemarked) to BS EN 13476-2:2007

- ULTRA3 fittings certified (Kitemarked) to BS EN 1401-1:2009

- 100/110mm and 150/160mm sewer pipe manufactured in 3m and 6m lengths for house/plot drainage

- 100/100mm, 150/160mm, 185/200mm, 225/250mm and 300/315mm sewer pipe manufactured in 3m lengths in accordance with water authority requirements

SN8 System Approval

The ULTRA3 system, manufactured by DYKA, is made up of SN8 pipework to EN 13476-2 and SDR 41 fittings.

Pipework is certified (Kitemarked) to BS EN 13476-2. Within this standard Section 9.2 states: "The mechanical characteristics of solid-wall fittings are described in the relevant product standards (EN 1401-1, EN 1852-1 or EN 12666-1) or EN 13476-3."

100/110 - 300/315mm ULTRA3 Sewer Drainage System

Pipe

| Description | Pipe Diameter (ID/OD) mm | ||||

|---|---|---|---|---|---|

| 100/110 | 150/160 | 185/200 | 225/250 | 300/315 | |

| Single Socket Solid Pipe x 3m | 01864UP3S | 01866UP3S | 02868UP3S | 028610UP3S | 028612UP3S |

| Single Socket Solid Pipe x 6m | 01864UP6S | 01866UP6S | - | - | - |

| Single Socket Perforated Pipe x 6m | 01064DP6SP | 01066DP6SP | - | - | - |

Couplers

| Description | Pipe Diameter (ID/OD) mm | ||||

|---|---|---|---|---|---|

| 100/110 | 150/160 | 185/200 | 225/250 | 300/315 | |

| Single Socket Coupler | 01024D69 | 01026D69 | - | - | - |

| Double Socket Coupler | 01024D20D | 01026D20D | 02828D20D | 028210D20D | 028212D20D |

| Double Socket Slip Coupler | 01024D20DSC | 01026D20DSC | 02828D20DSC | 028210D20DSC | 028212D20DSC |

Double Socket Bends

| Description | Pipe Diameter (ID/OD) mm | ||||

|---|---|---|---|---|---|

| 100/110 | 150/160 | 185/200 | 225/250 | 300/315 | |

| 15° Double Socket Bend | 01024D29D | 01026D29D | - | - | - |

| 30° Double Socket Bend | 01024D27D | 01026D27D | - | - | - |

| 45° Double Socket Bend | 01024D25D | 01026D25D | - | - | - |

| 90° Double Socket Bend | 01024D23D | 01026D23D | - | - | - |

| 90° Double Socket Rest Bend | 01024D21D | - | - | - | - |

| 0-30° Double Socket Adjustable Bend | 01024DV40D | - | - | - | - |

Single Socket Bends

| Description | Pipe Diameter (ID/OD) mm | ||||

|---|---|---|---|---|---|

| 100/110 | 150/160 | 185/200 | 225/250 | 300/315 | |

| 15° Single Socket Bend | 01024D29 | 01026D29 | 02828D29 | 028210D29 | 028212D29 |

| 30° Single Socket Bend | 01024D27 | 01026D27 | 02828D27 | 028210D27 | 028212D27 |

| 45° Single Socket Bend | 01024D25 | 01026D25 | 02828D25 | 028210D25 | 028212D25 |

| 90° Single Socket Bend | 01024D23 | 01026D23 | 02828D23 | 028210D23 | 028212D23 |

| 90° Single Socket Rest Bend | 01024D21 | - | - | - | - |

| 0-30° Single Socket Adjustable Bend | 01024DV40 | - | - | - | - |

Equal Junctions

| Description | Pipe Diameter (ID/OD) mm | ||||

|---|---|---|---|---|---|

| 100/110 | 150/160 | 185/200 | 225/250 | 300/315 | |

| 45° Triple Socket Junction | 01024D33D | 01026D33D | - | - | - |

| 90° Triple Socket Junction | 01024D30D | 01026D30D | - | - | - |

| 45° Double Socket Junction | 01024D33 | 01026D33 | 02828D33 | 028210D33 | 028212D33 |

| 90° Double Socket Junction | 01024D30 | 01026D30 | - | - | - |

Unequal Junctions

| Description | Pipe Diameter (ID/OD) mm | ||||

|---|---|---|---|---|---|

| 100/110 | 150/160 | 185/200 | 225/250 | 300/315 | |

| 45° Triple Socket Junction (110mm) | - | 010264D33D | - | - | - |

| 90° Triple Socket Junction (110mm) | - | 010264D30D | - | - | - |

| 45° Double Socket Junction (110mm) | - | - | 028284D33 | - | - |

| 45° Double Socket Junction (160mm) | - | - | 028286D33 | - | 0282126D33 |

| 45° Double Socket Junction (200mm) | - | - | - | 0282108D33 | - |

| 45° Single Socket Junction (110mm) | - | 010264D33 | - | - | - |

| 45° Single Socket Junction (160mm) | - | - | - | 0282106D33 | - |

| 45° Single Socket Junction (200mm) | - | - | - | - | 0282128D33 |

| 90° Single Socket Junction (110mm) | - | 010264D30 | - | - | - |

Reducers & Adaptors

| Description | Pipe Diameter (ID/OD) mm | ||||

|---|---|---|---|---|---|

| 100/110 | 150/160 | 185/200 | 225/250 | 300/315 | |

| Universal Rainwater Adaptor | 01024D76 | - | - | - | - |

| Universal Waste Adaptor | 01024DW200 | - | - | - | - |

| 160mm x 110mm Level Invert Reducer | - | 010264DT | - | - | - |

| 200mm x 160mm Level Invert Reducer | - | - | 028286DT | - | - |

| 250mm x 160mm Level Invert Reducer | - | - | - | 0282106DT | - |

| 250mm x 200mm Level Invert Reducer | - | - | - | 0282108DT | - |

| 315mm x 250mm Level Invert Reducer | - | - | - | - | 02821210DT |

Access Fittings

| Description | Pipe Diameter (ID/OD) mm | ||||

|---|---|---|---|---|---|

| 100/110 | 150/160 | 185/200 | 225/250 | 300/315 | |

| Oval Alu Sealed Rodding Eye | 01024DRE | 01026DRE | - | - | - |

| Square Alu Sealed Rodding Eye | 01024DRESS | - | - | - | |

| Screwed Access Cap | 01024D64 | 01026D64 | - | - | - |

| Protect Cap (TC) | 01024D67 | 01026D67 | 02828D67 | 028210D67 | 028212D67 |

| Socket Plug | 01024D68 | 01026D68 | 02828D68 | 028210D68 | 028212D68 |

Gullies & Traps

| Description | Pipe Diameter (ID/OD) mm | ||||

|---|---|---|---|---|---|

| 100/110 | 150/160 | 185/200 | 225/250 | 300/315 | |

| Round Plain Bottle Gully | 01024DBG | - | - | - | - |

| Round Back Inlet Bottle Gully | 01024DBGBI | - | - | - | - |

| Square Back Inlet Bottle Gully | 01024DG89 | - | - | - | - |

| 45° Universal Gully Trap | 01024DG90 | - | - | - | - |

| Lowback P Trap | 01024DG91 | - | - | - | - |

| Square Hopper Head | 01024DG92 | - | - | - | - |

| Rectangular Hopper Head | 01024DG93 | - | - | - | - |

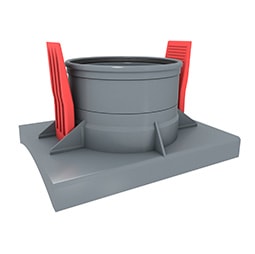

PP Inspection Chambers (PPIC)

| Description | Pipe Diameter (ID/OD) mm | ||||

|---|---|---|---|---|---|

| 100/110 | 150/160 | 185/200 | 225/250 | 300/315 | |

|

110mm PPIC Chamber Base ⌀ 320mm

170mm deep, 3 x 110mm inlets

|

01024DSMB3 | See 160mm PPIC Chambers below | See AXEDO® | See AXEDO® | See AXEDO® |

|

110mm Level Invert PPIC Chamber Base ⌀ 320mm

220mm deep, 5 x 110mm inlets

|

01024DSMB5 | ||||

|

⌀ 320mm Chamber Riser x 190mm

with sealing ring

|

01024DSMR190 | ||||

|

⌀ 320mm Chamber Riser x 400mm

with sealing ring

|

01024DSMR400 | ||||

|

⌀ 320mm PPIC A15 Circular Cover & Frame

|

01024DSMCDR | ||||

|

⌀ 320mm PPIC A15 Square Cover & Frame

|

01024DSMCDS | ||||

|

110mm PPIC Chamber Base ⌀ 450mm

250mm deep

|

01024DLMB | - | See AXEDO® | See AXEDO® | See AXEDO® |

|

160mm PPIC Chamber Base ⌀ 450mm

160mm main branch; 2 x 110mm 45° inlets; 2 x 160mm 90° inlets; 280mm deep

|

- | 01026DLMB | |||

|

⌀ 450mm Chamber Riser x 235mm

with sealing ring

|

01024DLMR | 01024DLMR | |||

|

⌀ 450mm PPIC A15 Round Cover & Frame

|

01024DLMCR | 01024DLMCR | |||

|

⌀ 450mm PPIC A15 Square to Round Cover & Frame

|

01024DLMCS | 01024DLMCS | |||

375/400 - 600/630mm ULTRA3 Sewer Drainage System

Pipe

| Description | Pipe Diameter (ID/OD) mm | ||||

|---|---|---|---|---|---|

| 375/400 | 475/500 | 600/630 | |||

| Single Socket Solid Pipe x 3m | 029616UP3S | 029620UP3S | 029624UP3S* | ||

Couplers

| Description | Pipe Diameter (ID/OD) mm | ||||

|---|---|---|---|---|---|

| 375/400 | 475/500 | 600/630 | |||

| Double Socket Coupler | 029216D20D | 029220D20D | 029224D20D | ||

| Double Socket Slip Coupler | 029216D20DSC | 029220D20DSC | 029224D20DSC | ||

Single Socket Bends

| Description | Pipe Diameter (ID/OD) mm | ||||

|---|---|---|---|---|---|

| 375/400 | 475/500 | 600/630 | |||

| 15° Single Socket Bend | 029216D29 | 029220D29 | 029224D29 | ||

| 30° Single Socket Bend | 029216D27 | 029220D27 | 029224D27 | ||

Unequal Junctions

| Description | Pipe Diameter (ID/OD) mm | ||||

|---|---|---|---|---|---|

| 375/400 | 475/500 | 600/630 | |||

| 45° Double Socket Junction (160mm) | 0292166D33 | 0292206D33 | 0292246D33 | ||

Access Fittings

| Description | Pipe Diameter (ID/OD) mm | ||||

|---|---|---|---|---|---|

| 375/400 | 475/500 | 600/630 | |||

| Protect Cap (TC) | 029216D68 | 029220D68 | 029224D68 | ||

| Socket Plug | 029216D67 | 029220D67 | 029224D67 | ||

Saddle Connections

| Description | Code |

|---|---|

| PVCU Saddle Connection To Concrete (150mm) | 029226DSAD |

| 400mm PVCU Saddle Connection To ULTRA3 (160mm) | 0292166DSAD |

| 500mm PVCU Saddle Connection To ULTRA3 (160mm) | 0292206DSAD |

| 600mm PVCU Saddle Connection To ULTRA3 (160mm) | 0292246DSAD |

Essentials

Air Test Kits & Bags

| Description | Code |

|---|---|

| Air Testing Kit | 200179109 |

| Pump | 200184011 |

| 110mm Air Test Bag | 200183032 |

| 160mm Air Test Bag | 200183051 |

| 250/315 Air Test Bag | 200183062 |

| 400mm Air Test Bag | 200187375 |

| 500mm Air Test Bag | 200187470 |

| 630mm Air Test Bag | 200187600 |

Chamfer Tools

| Description | Code |

|---|---|

| Hand rasp | 2001RASP |

| 110mm drill tool | 2001CHAMFER |

| Cordless router | 2001ROUTER |

| Cutting tool for router | 2001BEVCUTTER |

Accessories

Lubricant

| Description | 0.5kg | 1.0kg | 2.5kg |

|---|---|---|---|

| Pipe Jointing Lubricant | 2001LUB500 | 2001LUB1 | 2001LUB2.5 |

Warning Tape

| Description | Code |

|---|---|

| Red Detectable Warning Tape - FOUL SEWER | 2003DETMESHSB |

| Red Warning Tape - FOUL SEWER | 2003FOULSEWECON |

Handling

Extra care should be taken when handling PVC pipes in cold weather. Correct PPE should be worn at all times when handling the pipes, gloves, hard hat, hi-visibility clothing and safety footwear.

If bundles of ULTRA3 are to be removed from a vehicle mechanically, nylon belt slings or fork lifts with smooth forks can be used and making sure no metal, hooks or chains come into direct contact with the pipe.

Storage

Pipes must be stored on a flat surface and away from anything that is likely to cause damage. Bundles of ULTRA3 can be stored up to three high without any support barriers.

Care must be taken when removing pipes from bundles as the straps are under extreme strain and may flail when cut.

Pipes of different sizes should be stacked separately, if this is not possible the larger pipes should be stacked below the smaller.

Approvals

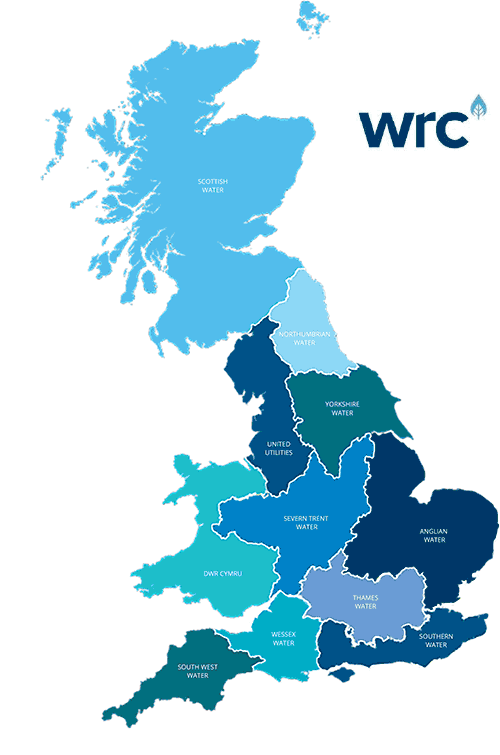

ULTRA3 is approved and accepted by water authorities across the UK and is included in the following publications:

- Sewers for Adoption and Sewers for Scotland, under its generic name of Thermoplastic Structured Wall Sewer Pipe, in sections E 2.22 & 4.2.22 respectively.

- Civil Engineering Specification for the Water Industry (CESWI), under its generic name of Thermoplastic Structured Wall Sewer Pipe.

WIS 4-35-01

WIS 4-35-01 outlines additional testing requirements for thermoplastic structured wall pipes in accordance with Sewers for Adoption and Sewers for Scotland covering: resistance to internal puncture; resistance to water jetting; and longitudinal bending.

ULTRA3 is the first PVC-U pipe that has been independently tested by WRc and exceeds 4000 psi jetting pressure. ULTRA3 has been extensively tested in all three areas and exceeds the requirements of WIS 4-35-01.

UK REACH Compliance Statement

- The use of PVC recyclate from external sources benefits the sustainable development of our society.

- PVC piping systems with recyclate are of the highest quality, have a better CO2 footprint, limit the use of new raw materials and have a lifespan of more than a hundred years.

- Technical research has shown that PVC piping systems can be reused (recycled) at least seven times.

- Moreover, DYKA, as manufacturer of ULTRA3, stopped using lead (stabilizers) in PVC piping systems some years ago.

- However, pipes with PVC recyclate from used PVC pipes may contain traces of lead.

- Any traces of lead from the recycled material are embedded in the polymer matrix and under normal conditions are not released during the life of the product.

- The use of recycled material from used PVC-U products is monitored on the basis of the relevant product standards for pressureless applications.

- Since the inclusion of lead on the REACH candidate list of December 2012, manufacturers of PVC products that may contain lead (stabilizer) are obliged to inform their customers about this (REACH Regulation (EC) No. 1907/2006, Article 33).

- As the legislation on substances is constantly evolving, this statement (Version 1 July 2013) will be updated as necessary.