The short answer is that it all disappears into your home's drainage system, which is an essential yet often unseen network of pipes that plays a critical role in managing wastewater and surface water, thereby protecting your property and the environment. But where does 110mm drainage pipework fit into that?

For many homeowners, the terms "drainage" and "pipework" may seem intimidating. With various materials available, standards to consider, and fittings on offer, how can you ensure you're choosing the right pipe for your specific needs? Understanding the basics can save you headaches (and money) in the future, which is why we have written this article to assist you.

What is a 110mm Drainage pipe?

A 110mm drainage pipe is the standard and most commonly used size of pipe for Underground Drainage Systems in the UK and many other regions. Often referred to as "4-inch drainage pipe" (110mm is its metric equivalent), it is primarily designed to transport foul water (waste from toilets, sinks, baths, and washing machines) and surface water (rainwater from roofs and paved areas) away from residential, commercial, and industrial properties.

Typically made from durable materials like uPVC or, in older systems, vitrified clay, 110mm pipes are robust, resistant to corrosion, and feature a smooth bore to ensure efficient flow and minimise blockages. They form the backbone of a property's connection to the main sewer network or other waste disposal systems, such as septic tanks or soakaways.

How Your House Drainage System Works

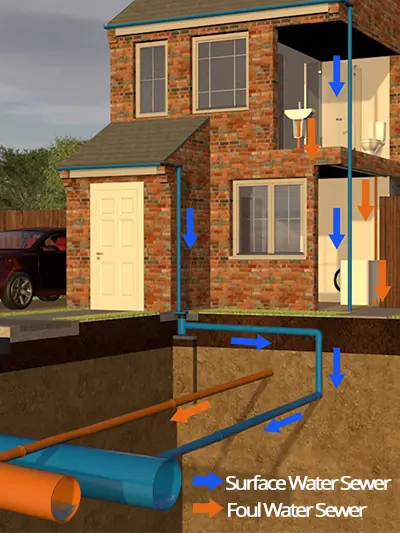

At its simplest, your home drainage system is designed to carry wastewater away from your property by gravity. It typically consists of two main parts:

Foul Water Drainage

Foul water pipes take all the wastewater from your toilets, sinks, baths, showers, washing machines, etc., and channel it away from your property.

Surface Water Drainage

Surface water pipes collect rainwater from your roof (via downpipes and gullies) and paved areas, like patios and driveways, directing it away from your property to prevent flooding.

All these different flows eventually converge into a larger network of underground drainage pipes, often leading to an inspection chamber or manhole before connecting to the main public sewer system or an off-mains sewage treatment plant or storage tank.

What is 110mm Drainage Pipe Used For?

110mm drainage pipe is the standard size for most domestic foul water (waste from toilets, sinks, baths) and surface water (rainwater from roofs and paved areas) drainage systems in the UK. Its robust diameter ensures efficient flow and helps prevent blockages, making it suitable for:

- Main waste lines - Carrying effluent from multiple fixtures away from your house.

- Connecting to public sewers - Forming the link between your private system and the public network.

- Running branch lines - Connecting individual fixtures or rainwater downpipes to the main drainage system.

- Surface water dispersal - Efficiently moving rainwater away from your foundations.

- Gully connections - Linking rainwater gullies to the underground drainage network.

Drainage Pipe Materials – uPVC vs Clay

The material of your 110mm drainage pipe is crucial for its performance, durability, and suitability for different applications. Here are the most common types you'll encounter:

uPVC (Unplasticized Polyvinyl Chloride)

uPVC (also known as PVC-U or PVCu) is suitable for almost all domestic foul and surface water drainage, particularly underground applications. It is by far the most popular choice for modern drainage.

Pros

uPVC drainage pipes are:

- Lightweight - Easier to transport and handle on site, reducing installation effort.

- Durable - Resistant to impacts and able to withstand various ground conditions, ensuring longevity.

- Easy to cut and join - Simple to modify and connect on-site, speeding up installation.

- Corrosion resistant - Unaffected by chemicals found in wastewater or soil, maintaining integrity over time.

- Relatively inexpensive - Offers a cost-effective solution for drainage systems without compromising performance.

- Feature a smooth bore - Minimises friction and prevents build-up of debris, reducing the risk of blockages.

- Long service life - When designed, manufactured, and installed correctly (according to current standards), they have an expected service life well in excess of 100 years, as stated by The European Plastic Pipes and Fittings Association (TEPPFA), offering a reliable long-term solution.

Cons

uPVC drainage pipes are also:

- Susceptible to thermal expansion and contraction - Can expand and contract with temperature fluctuations, requiring careful consideration during installation to prevent stress on the system.

- Less rigid than traditional materials - May require more extensive support or careful bedding in certain ground conditions compared to materials like clay or concrete.

- Susceptible to UV degradation - Prolonged exposure to direct sunlight before installation can weaken the material over time, affecting its long-term durability. uPVC pipes installed above-ground are made from UV Stabilised uPVC to prevent this, which is why it is important to know the difference between underground drainage pipe and above-ground drainage pipe.

Clay (Vitrified Clay)

Clay is best suited to older properties, heavy-duty industrial applications, or where heritage considerations are paramount. Modern installations rarely opt for clay unless they need to match existing systems.

Pros

Clay drainage pipes are:

- Extremely durable - Capable of withstanding significant external pressures and ground movement without deforming.

- Resistant to chemical attack - Unaffected by corrosive substances in wastewater or aggressive soil conditions, ensuring long-term integrity.

- Excellent in high-temperature environments - Ideal for applications where hot water or waste might be discharged.

- Very long lifespan - Known to last well over 100 years, providing a highly reliable and long-term solution.

Cons

Clay drainage pipes are also:

- Heavy - Can be difficult and labour-intensive to transport and install, potentially requiring specialised equipment.

- More fragile during transport and installation - Susceptible to cracking or breakage if not handled with care, leading to potential waste and delays.

- Typically more expensive than uPVC - Higher material and installation costs compared to uPVC alternatives.

- Requires more skilled labour to fit - Installation can be more complex, often needing specialist skills and techniques.

What is the Difference Between Above-Ground and Below-Ground 110mm Drainage Pipes?

Both above-ground and below-ground drainage systems use 110mm pipes to carry foul (and sometimes surface) water. However, while their nominal diameters are the same, each system requires products tailored to its specific environment. The key differences lie in durability, resistance to external factors, colour, and relevant British Standards (BS EN). Let’s take a closer look at each type:

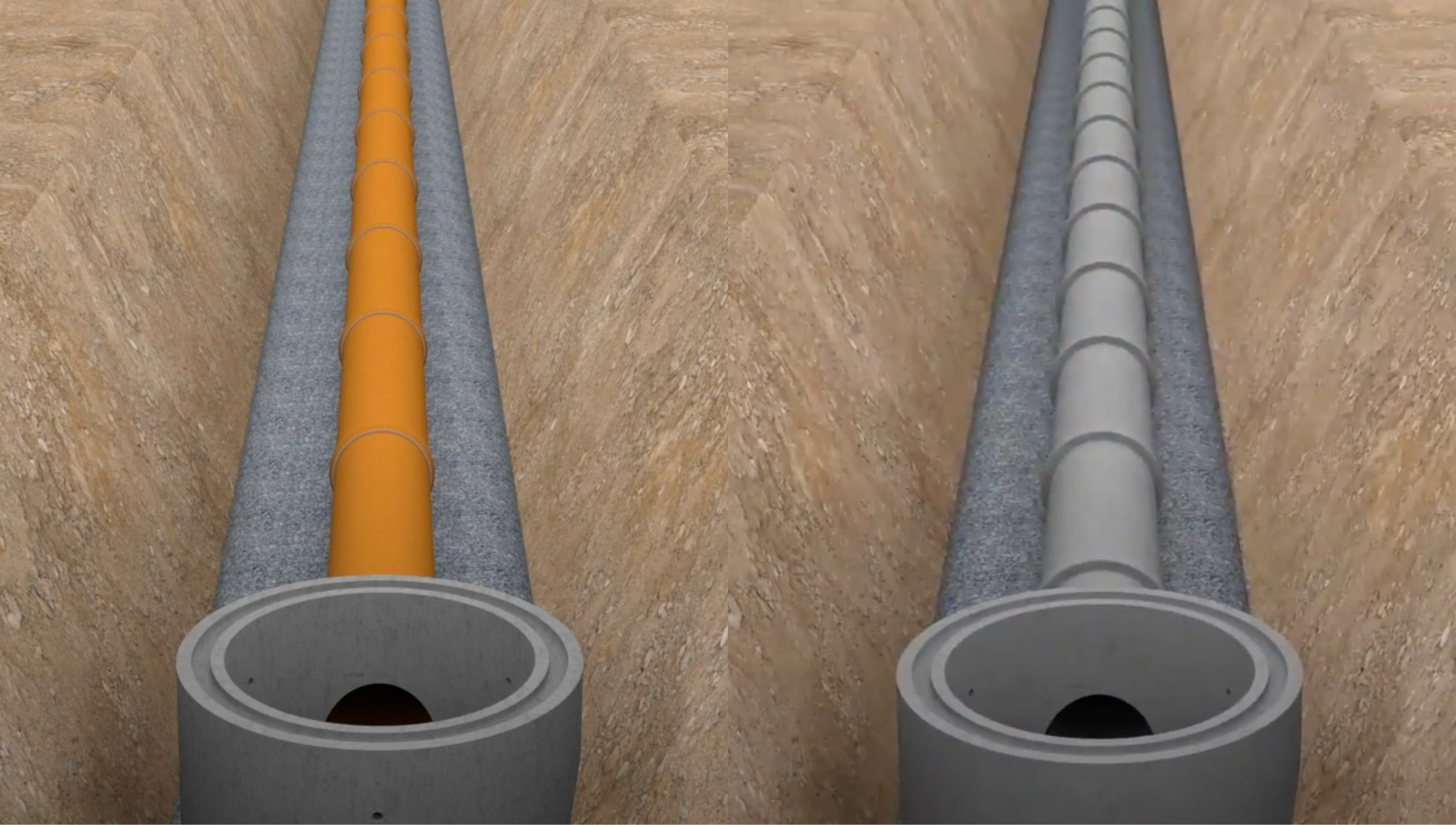

Below-Ground - Underground Drainage Pipes

110mm Underground Drainage Pipes are, unsurprisingly, designed to be buried beneath the earth, often under significant load from soil, vehicles, or structures. Their key characteristics are:

- Durability - Underground drainage pipes must be highly robust and resistant to crushing, ground movement, and chemical attack from soil or effluent. They are built to withstand external pressures.

- Appearance - These pipes are typically manufactured in a terracotta (orange/brown) colour, which is an industry standard to easily identify them as underground drainage.

- Standards - They primarily conform to BS EN 1401 or BS EN 13476 (for pipes containing recycled material), which specify requirements for non-pressure underground drainage and sewerage systems.

Above-Ground - Soil Pipes

110mm Above-Ground Drainage Pipes are typically used as "soil stacks", either vertically or horizontally, on the interior or exterior of a property, to collect waste from toilets, baths, sinks, and other fixtures before connecting to the underground system.

- Durability - While still strong, above-ground pipes don't face the same external crushing pressures as underground pipes and, therefore, don’t need to be as strong. Their primary concerns are impact resistance from accidental knocks and UV degradation from sunlight, for which the plastic must be UV Stabilised.

- Appearance - They are commonly manufactured in grey, black, or white uPVC to blend with building aesthetics. Black pipes often have enhanced UV resistance.

- Standards - Primarily conform to BS EN 1329-1, which specifies requirements for plastic piping systems for soil and waste discharge (low and high temperature) within the building structure.

110mm Drainage Fittings – Building the Drainage System

A pipe is only as good as its connections, so a comprehensive range of drainage pipe fittings for 110mm systems is essential for any successful drainage project. These will likely include:

- 110mm Drainage Bends - For changing direction (e.g., 45-degree, 90-degree).

- 110mm Drainage Junctions - For connecting branch lines to the main pipe (e.g., Y-junctions, T-junctions).

- 110mm Drainage Reducers - For connecting pipes of different diameters (though less common with 110mm as a primary size).

- 110mm Drainage Couplers/Connectors - For joining straight lengths of pipe.

- 110mm Drainage Access Pipes/Caps - For creating inspection points.

It is essential to ensure that all your fittings are compatible with your chosen pipe material and meet the same quality standards to achieve a watertight and durable system. Selecting the matching pipes and fittings from the same brand is always advisable when possible.

110mm Drainage Regulations and Standards

When choosing 110mm drainage pipes and fittings, always ensure they comply with the relevant British Standards (BS EN) and Building Regulations. Understanding the relevant regulations and standards is crucial for ensuring drainage systems are installed correctly, safely, and in compliance with legal requirements. In the UK, several key standards and building regulations govern the manufacture, use, and installation of drainage pipes.

Standards for uPVC Drainage Pipes

For uPVC drainage pipes, the following two primary European Standards, adopted as British Standards (BS EN), are particularly relevant:

- BS EN 1401: Plastics piping systems for non-pressure underground drainage and sewerage – Unplasticized poly(vinyl chloride) (PVC-U)

This standard specifies the requirements for solid-wall uPVC pipes and fittings used in non-pressure underground drainage and sewerage systems, both outside and sometimes within building structures. It covers dimensions, material properties, and performance criteria to ensure the pipes are suitable for conveying foul water and surface water under gravity. Products complying with BS EN 1401 are typically made from virgin uPVC.

- BS EN 13476: Plastics piping systems for non-pressure underground drainage and sewerage – Structured-wall piping systems of unplasticized poly(vinyl chloride) (PVC-U), polypropylene (PP) and polyethylene (PE)

This standard applies to structured-wall plastic piping systems. Crucially, it allows for the incorporation of recycled materials in the pipe's construction, provided the final product still meets rigorous performance and durability requirements. This standard supports more sustainable manufacturing practices while ensuring the pipes are fit for underground drainage applications.

Standards for Clay Drainage Pipes

Clay drainage pipes, known for their durability and resistance, are primarily covered by the BS EN 295 series:

- BS EN 295-1: Vitrified clay pipe systems for drains and sewers – Requirements for pipes, fittings and joints

This is the core standard in the series, setting out the requirements for vitrified clay pipes, fittings, and their flexible joints used in buried drain and sewer systems. It covers systems for conveying wastewater (including domestic wastewater, surface water, and rainwater) under gravity. The standard specifies different strength classes, joint dimensions, lengths, and fitting types to ensure reliable performance. Other parts of the EN 295 series cover specific components like adaptors, perforated pipes, and test methods.

Building Regulations Part H: Drainage and Waste Disposal

In addition to product-specific standards, all drainage installations in the UK must comply with Building Regulations Part H (Drainage and Waste Disposal). This Approved Document provides guidance on how to meet the legal requirements for drainage and waste management in and around buildings. It covers various aspects to ensure public health, safety, and environmental protection. Some of the key sections pertaining to the use of 110mm drainage pipe include:

- H1: Foul water drainage – This section details requirements for systems collecting and transporting foul water (from toilets, sinks, etc.) away from buildings to a public sewer, private sewer, or an appropriate treatment system (like a septic tank or cesspool). It includes guidance on pipe sizes, traps, seals, connections, and ventilation.

- H3: Rainwater drainage – Covers the provision of adequate systems for draining rainwater from roofs and paved areas, prioritising discharge to soakaways or other infiltration systems, then watercourses, and finally sewers.

- H5: Separate systems of drainage – Emphasises the importance of separate systems for foul water and surface water to prevent contamination and manage flows efficiently.

Always consult the building regulations for drainage or a qualified professional to ensure your installation is compliant. Selecting pipework that meets the correct standards and installing it according to relevant regulations isn't just about avoiding legal problems; it's about ensuring safe, efficient, and durable drainage systems that are robust, perform effectively, and protect both public health and the environment.

How do you connect 110mm drainage pipes and fittings?

Connecting 110mm drainage pipes and fittings depends primarily on the pipe material and whether it's for above-ground or below-ground use. Here is a quick look at the main options:

Connecting 110mm uPVC Below-Ground Drainage Pipes (Terracotta/Orange)

The most common connection method for 110mm underground drainage pipes and fittings is push-fit (or ring seal) joints. The plain end of the pipe or fitting is simply pushed into the rubber-sealed socket of another fitting or pipe. A lubricant (silicone spray or a purpose-made pipe lubricant) is typically applied to the pipe end and the seal to facilitate an easy, watertight connection. These joints allow for slight movement due to ground settlement or thermal expansion.

Connecting 110mm uPVC Above-Ground Drainage Pipes (Grey/Black/White)

Above-ground drainage pipes used for soil systems typically use either push-fit connections or solvent weld connections.

Push-fit Joints

Push-fit joints (also known as Ring Seal joints) are very common in modern above-ground drainage systems, particularly for vertical soil stacks. They function in the same way as those used in below-ground systems, with the plain end of a pipe or fitting being pushed into the rubber-sealed socket of another to form a watertight seal. The added benefit to using push-fit in above-ground systems is that they are easy to disassemble and modify as needed, since the joints can simply be pulled apart to release the pipe. This makes them an ideal choice for refurbishment projects where the existing soil pipe system needs to be replaced or extended.

Solvent Weld Joints

Solvent weld joints are another popular method, particularly for more rigid or horizontal runs. A solvent cement is applied to both the pipe end and the inside of the fitting socket, creating a strong, permanent chemical bond as the solvent evaporates. This method does not allow for movement or non-destructive disassembly.

For more information on how to choose between push-fit and solvent weld connections for soil systems, have a read of our "Ring Seal or Solvent Weld - which soil pipe system is better?" article.

Connecting 110mm Clay Drainage Pipes

Modern clay pipes typically use flexible rubber ring joints. A rubber seal is placed into the spigot (socket) end of one pipe, and the plain end of the next pipe is pushed into it. Use of a suitable lubricant is essential for this. Older clay pipes, however, are likely to have been joined using mortar or bitumen, which is less common in new installations due to its rigidity and potential for cracking.

Regardless of the method, ensuring clean pipe ends, proper lubrication (where applicable), and correct alignment are vital for creating secure, watertight, and long-lasting drainage connections. Always refer to the manufacturer's specific instructions for the best results.

How to install 110mm Drainage Pipes

Installing drainage pipes correctly is crucial for the long-term health and efficiency of any property's wastewater system. While the basic principles for above-ground and below-ground 110mm drainage systems both involve connecting pipes and fittings, the actual process differs, and both require precision to avoid costly future issues.

Here is a quick overview of each type of installation:

Installing 110mm Underground Drainage Pipes

Installing 110mm drainage pipe underground will typically be for either adoptable sewer systems or house/plot drainage systems. However, the processes are largely the same for each.

- Planning & Excavation - The process starts with careful planning, marking out the trench routes, and calculating the correct depths and gradients (slopes) required for gravity flow. Trenches are then excavated to these exact specifications, ensuring a stable and level bed for the pipes.

- Bedding - A layer of granular material (such as pea shingle or sharp sand) is laid in the trench to create a uniform, supportive base for the pipes, preventing stress points.

- Laying Pipes - When installing 110mm underground drainage pipes, it is essential to start from the lowest point (downstream) and work back towards the highest point (upstream). This approach helps ensure that the correct gradient (slope) is maintained consistently throughout the run, allowing gravity to effectively carry wastewater away. Furthermore, the socketed end of each pipe should always face upstream. This is vital for system integrity, as directing the flow into the socket helps prevent effluent from escaping the joint in the event of any minor compromise, ensuring a more reliable and watertight connection as waste flows downstream.

- Connecting Fittings - Utilise suitable fittings, such as bends and junctions, to construct the planned system, connecting them to the pipes using push-fit (ring seal) joints. Lubricant should be applied to the pipe ends and rubber seals to ensure easy, watertight connections.

- Testing & Backfilling - Once laid, the system is typically water-tested to check for leaks. After successful testing, the pipes are carefully surrounded with more granular material (sidefill and initial backfill) before the trench is fully refilled with excavated soil, ensuring no sharp objects can damage the pipe.

- Key Consideration - Maintaining the correct continuous gradient is vital to prevent blockages and ensure efficient waste removal. For more information, refer to our “Underground Drainage: Installation and Principles” article.

For more information about installing underground drainage, have a look at our Underground Drainage: Installation and Principles article.

Installing 110mm Above-Ground Drainage Pipes

Installing 110mm drainage pipe above-ground will typically be for soil pipe installations, building the soil stack that all other wastewater pipes within the property drain into. The process for this will usually involve:

- Route Planning - The path for the vertical soil stack and horizontal branch pipes (from toilets, sinks, etc.) is carefully planned, taking into account access, aesthetics, and connection points to fixtures.

- Fixing & Support - Pipes are securely attached to walls using pipe clips and brackets at designated intervals to prevent sagging and movement, especially at corners or connection points.

- Connecting - Connections are made to fixture outlets and then to the main stack using push-fit or solvent weld joints, depending on the system chosen.

- Ventilation - An essential part of above-ground drainage is the ventilation system (often a continuation of the soil stack or a separate vent pipe), which prevents siphoning of water from traps and allows air into the system.

- Key Consideration - Allowing for thermal expansion and contraction is important, particularly for long vertical runs, by using expansion joints or push-fit sockets that can accommodate movement.

DIY vs Professional 110mm Drainage System Installation?

While understanding the basics is helpful, installing 110mm drainage pipes, especially underground systems, is a complex task that requires specialised knowledge of Building Regulations Part H, correct gradients, soil conditions, and safety protocols for excavation. Mistakes can lead to serious issues like persistent blockages, leaks, structural damage, and costly repairs.

For most 110mm drainage installation projects, particularly those involving new runs, connections to public sewers, or significant groundwork, it is highly advisable to consult or hire a qualified professional. Their expertise ensures compliance, efficiency, and the long-term reliability of your crucial drainage system.

How to Maintain 110mm Drainage Pipes

Understanding your drainage system also means knowing how to look after it. You may assume, especially for pipes that run underground, that there isn’t really much you can do to maintain drainage systems once they are installed. Fortunately, this isn’t entirely true.

While repairs to damaged drainage are probably something you want to leave to the professionals, there are a number of simple habits and routines you can adopt when using your toilets and sinks, etc., that can help to prevent, or at least prolong, the need for any repair work to be undertaken. Here are some easy tips:

- Be mindful of what goes down the drain - Avoid pouring fats, oils, and greases down sinks, as they solidify and cause blockages.

- Use drain protectors - Place protectors or strainers over plugholes to catch hair and food debris. This helps prevent the build-up of material that can also cause blockages.

- Regular cleaning - Flush sinks with hot water, especially after greasy meals.

- Be careful with "flushable" wipes - Even if labelled flushable, these often don't break down and can cause significant blockages. Bin them instead.

- Clear gutters, downpipes, gullies and drains - Ensure rainwater can flow freely through your surface water drainage system by removing any accumulated debris from gutters (especially where they drain into downpipes), gullies (typically what downpipes drain in to), and external drains (such as channel drains in front of garages and around patios, etc.)

For more advice on maintaining your drainage systems, have a read of our related articles, "How do you clear blocked gullies?", "How to clean your gutters and downpipes", and "How to clean channel drains".

DIY vs Professional 110mm Drainage System Maintenance?

Understanding the role of 110mm drainage pipe and the basics of your home's drainage system empowers you to make better choices for your property. By learning a little about these hidden heroes, you can help ensure your home drainage runs smoothly for years to come. However, a little knowledge can sometimes be a dangerous thing, and it is important to know when you should step back from a problem and call in a professional.

For minor issues, such as a slow-draining sink or blocked toilet, a plunger or a simple drain cleaner might do the trick. However, for anything involving digging, connecting to the main sewer, or persistent blockages in your main 110mm pipes, it's always best to call a qualified plumber or drainage engineer. They have the specialist tools and expertise to diagnose and fix problems safely and effectively, ensuring your system complies with building regulations.

JDP’s 110mm Drainage Solutions

So, now that you know the where’s, why’s, and how’s of your household drainage, the next questions to ask are who can supply what you need, and what products are best suited to your needs.

Any good drainage supplier in the UK will stock both underground and above-ground 110mm drainage pipes and fittings that meet the relevant British Standards. Here at JDP, however, we’ve also tried to make the decision of which pipes you need as simple as possible. We offer three distinct, comprehensive ranges of PVC-U 110mm drainage pipes and fittings, focusing on sewer systems, house and plot drainage, and soil systems, with each range catering to its respective applications. Let’s take a quick look at each of them to see why we think they are the right choice for your drainage needs:

110mm Adoptable Sewer Range

Modern sewerage systems demand pipework and components that excel in installation, sustainability, and compliance. Our 110mm ULTRA3 Sewer Drainage System is specifically designed to meet these rigorous demands.

Why choose 110mm ULTRA3 for adoptable sewer systems?

Manufactured from durable PVC-U and Kitemarked to BS EN 13476-2 as an SN8-rated smooth-wall structured layer pipe, ULTRA3 is fully compliant with water authority requirements. Its robust construction makes it an ideal choice for adoptable sewers, ensuring long-term performance and reliability.

The system offers a comprehensive range of PVC-U pipes and fittings, available in sizes from 110mm to 630mm, providing direct connections to PPIC and AXEDO® chambers without the need for additional adaptors. This complete system can also be used for house and plot drainage.

Where ULTRA3 truly excels, however, is in its sustainability credentials. Made from uPVC in three layers, with an intermediary layer containing at least 40% recycled PVC from post-consumer and industrial waste, this smooth-walled, lightweight pipework has an 85% lower environmental impact on average compared to traditional materials such as clay and concrete.

Combining that with a service lifespan of over 100 years and certification to BS EN 13476-2 (pipework) and BS EN 1401-1:2009 (fittings), underlines ULTRA3’s quality and suitability for demanding applications, providing a modern solution for a sustainable future.

Buy ULTRA-3 Online

110mm House & Plot Drainage Range

For efficient and reliable drainage tailored specifically for individual properties, our 110mm DYKA Underground Drainage System is the ideal solution for house and plot drainage needs.

Why choose 110mm DYKA Underground for house and plot drainage?

The DYKA Underground range is a well-established and highly regarded choice for residential projects due to its proven reliability and ease of installation, providing a robust and dependable foundation for your domestic drainage requirements.

The traditional orange/terracotta PVC-U pipes and fittings are specifically designed to meet the demands of house and plot drainage, offering a dependable and recognised solution that integrates seamlessly with existing systems.

Buy DYKA UNDERGROUND Online

110mm Soil Pipe Range

110mm Soil Pipe Systems, made from PVC-U, are an efficient and modern way to connect above-ground foul and waste water pipes from sinks, toilets, and other sources to below-ground drainage pipe systems.

Why choose 110mm FloPlast pipes and fittings for soil systems?

Our range of FloPlast PVC-U 110mm soil pipes and fittings utilise push-fit joints and an innovative seal and snap cap system, making them watertight, easy to install and compact in size - a popular choice for domestic drainage systems.

From pipes, bends, couplers and brackets to access fittings, air admittance valves and boss terminals, our comprehensive range offers everything needed to create a plastic soil pipe system.

Buy FloPlast Soil Pipe Systems Online

Investing in a Reliable Drainage System

Your drainage system is a vital component of your property's infrastructure. By understanding the role of 110mm drainage pipe, the differences in materials, and the importance of standards and fittings, you're well-equipped to make informed decisions. Investing in quality pipework and proper installation will save you time, money, and hassle in the long run.

And that’s it for our basic guide to 110mm Drainage Pipes. Hopefully, this has given you a good grounding in the subject and answered some of the questions you might have had. If you are looking to dive in further, however, check out our other >Underground Drainage and Above-Ground Drainage articles for more advice, or review the FAQ section below for quick answers to some of the most common queries we receive.

If you are already sold on the benefits of our 110mm drainage ranges and want to purchase some for your project, our ULTRA3, DYKA UNDERGROUND, and FloPlast Soil pipes and fittings are all available to buy online in our store.

Should you have any further questions about 110mm drainage, contact us today. Our team of experts are always on hand to help with all of your civils and drainage needs.

Frequently Asked Questions about 110mm Drainage Pipes

What is 110mm drainage pipe used for?

110mm drainage pipe is the standard size for domestic foul water (toilet, sink, bath waste) and surface water (rainwater) underground drainage systems in the UK, used to convey waste away from properties to the main sewer or a septic system.

What is the difference between 110mm and 4-inch drainage pipe?

There is no difference; 110mm is the metric equivalent of a 4-inch drainage pipe. The industry has transitioned to metric measurements, but 4-inch is still a commonly understood imperial term.

What material are 110mm drainage pipes made from?

Most modern 110mm drainage pipes are made from uPVC (unplasticised polyvinyl chloride) due to its durability, light weight, ease of installation, and resistance to corrosion. Older systems might use vitrified clay.

How deep should 110mm drainage pipes be buried?

The minimum cover for 110mm uPVC drainage pipes is typically 600mm in gardens/fields and 900mm beneath light roads/drives. If these depths cannot be achieved, concrete encasement may be required for protection. Always consult Building Regulations Part H.

What is the minimum gradient for 110mm drainage pipe?

For 110mm foul water drainage with a WC connected, the minimum recommended gradient is generally 1:80 (a fall of 1 unit for every 80 units of length). For surface water drainage or foul water without a WC, a minimum of 1:40 is often acceptable, though 1:80 is still a good standard.

How long does 110mm uPVC drainage pipe last?

Properly installed 110mm uPVC drainage pipes can have a lifespan of 50 to over 100 years. Factors like soil conditions, installation quality, and external stresses can affect their longevity.

Can 110mm drainage pipe be used for surface water and foul water?

Yes, 110mm drainage pipe is suitable for both foul water (sewage and wastewater) and surface water (rainwater) drainage. Modern properties often use separate systems for each to comply with regulations.

What fittings are available for 110mm drainage pipe?

A wide range of 110mm fittings are available, including bends (45°, 90°), junctions (Y-junctions, T-junctions), couplers, reducers, access pipes, rodding eyes, and gully traps. These are designed for push-fit or solvent weld connections.

Do 110mm drainage pipes need to be certified?

Yes, 110mm underground drainage pipes sold in the UK must comply with relevant British Standards, primarily BS EN 13476 for uPVC pipes or BS EN 1401 for pipes and fittings, and meet the requirements of Building Regulations Part H to ensure quality and safety.

Why are some pipes certified to BS EN 13476 instead of BS EN 1401?

BS EN 1401 is the primary standard for solid-wall uPVC underground drainage, but it does not specifically cover the use of recycled content. BS EN 1347 covers structured-wall plastic piping systems that can use recycled polymers, ensuring these pipes still meet the strict performance and durability requirements for all underground drainage applications.

Can I connect a toilet to a 110mm drainage pipe?

Yes, 110mm is the standard and recommended minimum size for connecting a toilet to an underground drainage system, ensuring adequate capacity for solid waste.