Linear channel drainage plays a crucial role in managing surface water runoff in various residential, commercial, and industrial applications. These drainage systems, as their name would suggest, use linear channels to collect and transport surface water away from structures to help reduce the risk of flooding and enhance safety.

Channel drains are a practical, efficient, and affordable solution for managing surface water drainage from driveways, patios, and other outdoor areas. However, with so many types of linear channel drainage available in the market, deciding which one to choose can take time and effort. In this article, we will take a closer look at the different types of channel drain available in the UK, their loading applications, material types, and grating options.

It is essential to ensure that you choose the right solutions for your specific needs, so whether you are a DIYer, a small business owner, or a homeowner, this guide aims to help you make an informed decision.

What is a Channel Drain, and how does it work?

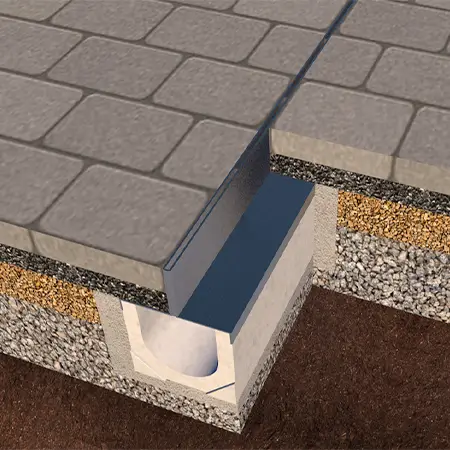

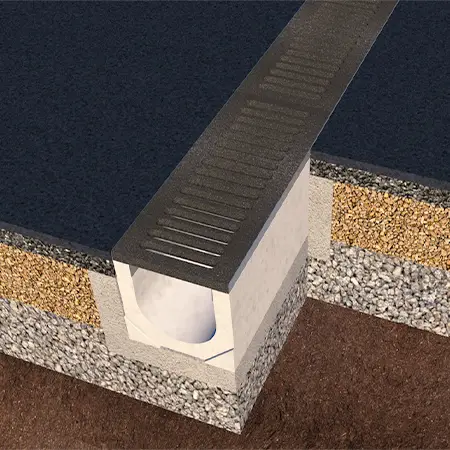

A typical channel drain consists of a long, narrow channel installed in the ground with a grate over the top that sits level with the surface. Usually situated in areas where a lot of surface water would otherwise pool, such as parking lots, driveways, and patios, they are also a good option in places where it may not be possible to install larger underground drainage pipe systems, such as areas with shallow soil or bedrock.

How do drainage channels work?

When water flows over the surface of a hard ground or paved area, gravity will direct it to the lowest point. This is where the channel drain system should be installed to provide surface water drainage. It does so by allowing the water to be collected and transported through the channel towards the outlet, which usually then flows into a larger drainage system. The grate or cover over the top of the channel prevents various types of debris from entering the system, which could otherwise clog the drain and reduce its effectiveness.

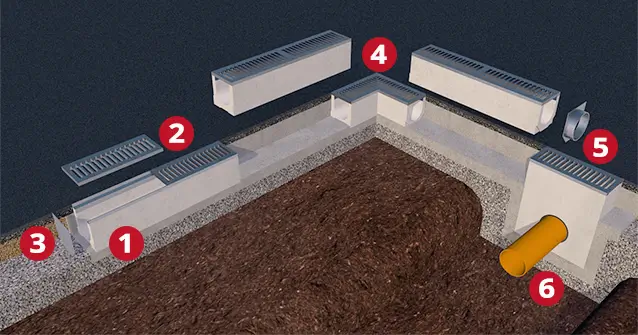

What are the components of a channel drain system?

A typical linear channel drainage system consists of the following components:

- Drainage Channel - The drainage channel, or channel body, is the long, narrow halfpipe-shaped lengths that get embedded in the ground to collect and discharge surface water from a catchment area. They are typically made of concrete, metal, or plastic and come in 1m lengths as standard.

- Grate or Cover - Channel drain gratings, sometimes referred to as drain covers, sit atop the channel body to allow surface water to drain in while providing protection against debris. They are typically made from iron, steel, or plastic and come in lengths of 500mm as standard (two per channel length).

- End Cap - Channel drain end caps offer a straightforward way to close channel runs as needed, aiding installers with quick and easy terminations. They are typically made from either steel or plastic.

- Junction Pieces & Bends - Channel drain junction pieces and bends are integral components that facilitate the seamless connectivity and directional control within channel drainage systems. Depending on the chosen material for the channel body, junctions and bends may need to be custom orders.

- Trash Box and Outlet Options - There are multiple methods for connecting linear channel drainage to underground pipes, including end caps with outlets for simple pipe connections, and modular trash boxes with sediment buckets to prevent debris from entering the pipe network. Trash boxes tend to also have multiple connection possibilities, such as an integrated PVC-U socket.

- Drainage pipe - Required to connect the channel drain outlet to the main drainage system.

Advantages of Channel Drains

Linear channel drains offer a number of advantages over other types of drainage systems, including:

- They are easy to install and maintain.

- They are effective in collecting and removing surface water.

- They are durable and can withstand heavy traffic.

- They are available in various sizes and materials to suit different applications.

Disadvantages of Channel Drains

Linear channel drains also have some disadvantages, including:

- They can look a bit unsightly in certain installations - unless you are willing to pay for more expensive decorative gratings.

- They can be a tripping hazard – depending on the type of grating you choose.

- They can get clogged with debris – again, depending on the grating option, as some have larger holes than others, which can let debris pass through more easily.

- They can be expensive – depending on the loading type and material you need for your application.

Do Channel Drains need to be installed with a fall to work?

Technically speaking, a channel drain does not have to be installed with a fall. As long as there is an outlet at the base of the channel, they can be installed perfectly level as the water will always run to the lowest point when in flow.

However, where possible, installing a fall of around 5mm per every 1m length of channel drain is recommended, as this will help ensure that the water flows freely through the channel and out of the outlet. Check out our “Channel Drain Installation Guide” for more information about how to properly install a channel drain system.

What are the main types of Channel Drain available?

First things first, let us clear up some terminology issues. Just as many people call all vacuum cleaners Hoovers or refer to all sticky tapes as Sellotape, the act of brand names being used as a common catch-all term crosses into this industry, too - and channel drains are a perfect example of this. One of the most commonly misused terms for channel drain is ACO Drain. However, ACO Drain is just a brand name and not a general term for all channel drain products.

Other common terms for channel train are linear drain and trench drain. These are descriptive names - linear drains because they are straight channels that join in lines to remove surface water and trench drains because they are effectively little trenches that surface water drains away into. They aren’t technically incorrect, but they have been replaced with the term channel drain in the wider drainage industry. Whether you know it as ACO Drain, Linear Drain, Trench Drain, or Channel Drain, the information in this article is still valid, though, as they all mean the same thing.

When it comes to channel drain, typically, there are two distinct types you need to know about: Slot Channel Drain and standard Channel Drain (i.e. channel drain with a grating). They both work the same way and do the same job, but there are some key differences that are worth keeping in mind when deciding which type to use.

What is the difference between Slot Channel Drains and Channel Drains with a Grating?

Slot Channel Drains, also known as Slotted Channel Drains, have a narrow slot that allows water to flow through but does not allow debris to enter the drain. This makes them a good choice for areas where it is important to retain debris, such as sidewalks, walkways, and patios. Slot channel drains are also heel-safe, which means they are not hazardous to people wearing high heels. However, slot channel drains have a lower flow rate than standard channel drains due to the narrower opening, allowing only a limited amount of water to flow through at any one time. They are also less resistant to bending and twisting, meaning they are best reserved for use in less highly trafficked applications.

| Pros: | Cons: |

|---|---|

| Low visual impact | Lower flow rate than channel drains with gratings |

| Very effective at retaining debris | |

| Heel-safe | Not as resistant to bending and twisting as channel drains with gratings. |

| Low maintenance |

Suitable applications:

Ideal for use in residential and commercial applications, such as balconies, terraces, and public spaces where the load capacity won’t exceed 25 tonnes. They are a popular choice for block paving installations as the minimalistic design leaves a much less noticeable break in the design.

Standard Channel Drains are the most common, versatile, and easy-to-spot type of linear channel drain. They have a removable grate that allows water to flow through, prevents larger types of debris from entering the drain, and allows any smaller debris that collects in the channel to be easily removed. This makes them a good choice for areas with heavy traffic or where a lot of debris must be filtered out of the water. Channel drains with gratings are also more resistant to bending and twisting than slot channel drains. However, the gratings themselves can be a hazard to people wearing high heels, and they require more maintenance than slot channel drains.

| Pros: (depending on the grating type) |

Cons: (depending on the grating type) |

|---|---|

| High flow rate | Can be less effective at retaining debris |

| More resistant to bending and twisting | Can be a hazard for high heel shoes |

| Suitable for a wider variety of applications | Require more maintenance |

Suitable applications:

Ideal for use in applications ranging from domestic driveways to airport runways, depending on the loading capacities of the channel and grating materials chosen – see section on loading classes for more about this.

Here is a quick table that summarises the key features of slot channel drains vs channel drains with a grating:

| Feature | Slot Channel Drain | Channel Drain with Grating |

|---|---|---|

| Flow Rate | Low | High |

| Debris Retention | High | Low |

| Resistance to Bending and Twisting | Low | High |

| Heel Safety | High | Depends on grating choice |

Note: The terms Slot and Slotted are often used interchangeably between channel drains with a narrow slot and channel drains with a grating that has two rows of slots. This can get confusing when searching for these products online, as even the big brands can’t seem to agree on which naming convention is correct. If you want the narrow opening, search for slot or slotted channel drain. If you want the grating with two rows of slots, search for channel drain with slot or slotted grating. This is probably the easiest way to avoid confusion.

The best type of channel drain for a particular application will depend on the project's specific needs. If retaining debris and protecting people from injury is essential, then a slot channel drain may be the best choice. If it is more important to have a high flow rate, heavy load resistance, and the ability to remove debris from the drain, then a channel drain with grating may be the best choice.

What are the most important factors to consider when choosing channel drainage?

Whether you are designing a stormwater management system, planning residential drainage, or installing driveway drainage at your home, there are three critical factors that must be considered – the loading class, the channel material type, and the grating option.

In this article, we shall give a brief overview of each to help highlight their importance when making your purchasing decision. For a more detailed look into these key factors, though, check out our companion articles - “Choosing the right loading for your channel drain application" and “Channel drain materials and gratings explained”.

Channel Drain Loading Classes

In linear channel drainage, loading classifications play a pivotal role in ensuring the optimal performance and longevity of the drainage system. These classifications act as a guide to help you select a channel drain that can withstand the expected weight and traffic intensity of your chosen installation environment.

In any application, channel drainage is likely to be subjected to at least one of three load types – pedestrian, static, or rolling.

Pedestrian Load

Pedestrian load refers to the weight exerted by people walking or standing on a surface. In the context of channel drain requirements, this load is relevant when the drainage system is installed in areas where only foot traffic is expected, such as pedestrian walkways, garden paths, and patio areas. The load from pedestrians is relatively consistent and distributed over a larger area.

Rolling Load

Static load refers to the weight of stationary objects or structures placed on a surface. In the case of channel drains, static load considerations are important when the drainage system is likely to encounter the weight of items such as parked cars, bicycles, or furniture. Unlike pedestrian load, static load involves concentrated weight in a particular area, which can lead to localised stress on the drain and its components.

Lateral Restraining Capability

Rolling load relates to the weight of moving or rolling objects, such as vehicles or trolleys. In terms of channel drain requirements, the rolling load is significant when the drainage system is installed in driveways, parking lots, or areas where vehicles are present. The load from rolling objects is dynamic and can vary based on the size and weight of the vehicles or equipment passing over the drain.

Channel drains are typically designed and categorised into load classes to accommodate these various load types. Load classes indicate the amount of weight a particular channel drain can bear without sustaining damage or compromising its functionality. Load classes are assigned based on factors like load type, anticipated traffic, and the materials used in the drain's construction.

Here's a brief rundown of loading classifications for linear channel drainage:

| A15 Load Class |

|

| B125 Load Class |

|

| C230 Load Class |

|

| D400 Load Class |

|

| E600 Load Class |

|

| F900 Load Class |

|

Understanding these loading classifications empowers you to make informed decisions when selecting a linear channel drainage system. By matching the appropriate loading class to your project's requirements, you ensure a drainage solution that can endure the anticipated traffic and weight demands, contributing to the efficiency and durability of your drainage infrastructure.

Channel Drain Material Types

The halfpipe-esque drainage length that makes up the base component of any channel drain can be made from a variety of materials. Some are more suitable than others for certain applications, so it’s worth considering each one in the context of your project requirements. Here is a brief summary of each material type.

For a more detailed look into their pros and cons, check out our companion article, “Channel drain materials and gratings explained”.

Plastic Channel Drains:

- Lightweight, easy to handle, and cost-effective solution.

- Resistant to chemicals and corrosion, making them suitable for various environments.

- Ideal for DIY projects and residential applications with light to medium loads.

- Popular for garden paths, driveways, and terraces due to their versatility.

Fibreglass/Glass-Reinforced Plastic Channel Drains:

- Lightweight, corrosion-resistant, and durable material choice.

- Well-suited for applications requiring chemical resistance and extreme temperature tolerance.

- Suitable for specialised scenarios, such as healthcare facilities or industrial settings.

- Exhibits a smooth interior surface for efficient water flow and easy maintenance.

Steel Channel Drains:

- Exhibits strength and load-bearing capacity, suitable for heavy-duty applications.

- Offers excellent corrosion resistance, particularly in coastal or chemically exposed environments.

- Versatile choice with various load classes for different traffic scenarios.

- Widely used in commercial, industrial, and municipal settings, often favoured for its sleek appearance.

Concrete Channel Drains:

- Durable and robust, suitable for heavy loads and industrial applications.

- Corrosion-resistant and capable of enduring harsh environments.

- Often chosen for their longevity and strength in high-traffic areas.

- Commonly used in commercial and industrial settings, including airports and car parks.

By exploring the distinct attributes of these linear channel drain materials, you'll gain a comprehensive understanding of their advantages and considerations, empowering you to make an informed choice that aligns perfectly with your drainage needs.

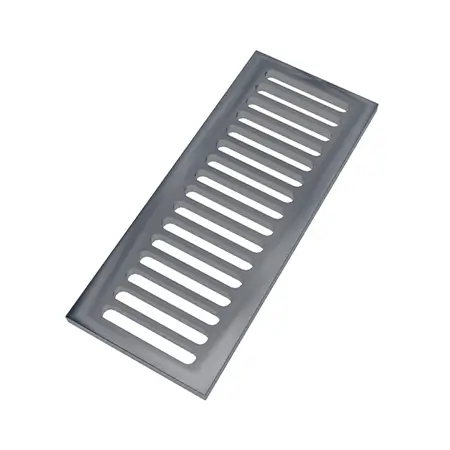

Channel Drain Grating Types

When it comes to channel drain systems, gratings serve as the unsung heroes, facilitating efficient water flow while preventing large debris from clogging the drainage path. Understanding the various types of channel drain gratings available is essential for selecting the right option that suits your project's needs. Here's a quick summary of the most common types of channel drain gratings:

Note: There seems to be no one standard naming convention in the channel drain industry, so the names we have used may not match those you see on other sites. However, the details are correct for the design styles shown in the images which should help you navigate any naming issues.

Standard Channel Drain Gratings:

- These are the most common types of gratings and feature a series of large parallel openings.

- Suitable for a wide range of applications, from residential driveways to commercial areas.

- Allow water to flow through while capturing larger debris.

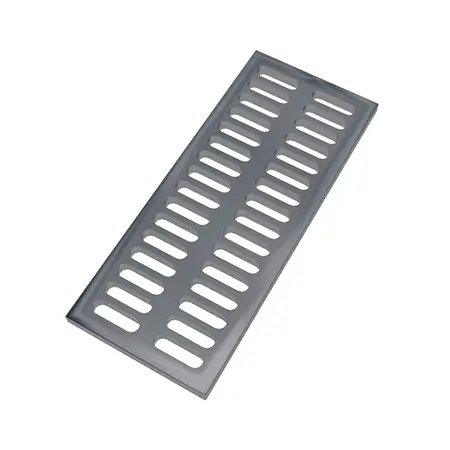

Slotted Channel Drain Gratings:

- Feature double row pattern of smaller slots side by side.

- Ideal for areas where aesthetics matter, as they offer a sleek and modern appearance.

- Efficiently drain water while offering increased surface area for debris capture.

Mesh Channel Drain Gratings:

- Consist of a fine mesh pattern that prevents even small debris from entering the drainage system.

- Suited for areas prone to collecting small debris, like stones and twigs.

- Commonly used in parks, gardens, and areas with heavy foliage.

Longitudinal Channel Drain Gratings:

- Characterised by elongated openings that run along the length of the grating.

- Designed to handle heavy loads and offer excellent water flow capacity.

- Often used in heavy-duty industrial settings and areas with substantial traffic.

Heelsafe Channel Drain Gratings:

- Specifically engineered to prevent high heels or small objects from getting stuck.

- Ideal for pedestrian areas, shopping centres, and spaces with foot traffic.

- Offer both functional water drainage and safety features.

Understanding these different types of channel drain gratings empowers you to make an informed choice that aligns with your project's specific requirements. By selecting the appropriate grating type, you ensure effective water drainage, prevent blockages, and contribute to the longevity and functionality of your drainage system.

Does the loading class of the drainage channel and the grating have to be the same?

Do the loading classes of the channel and grating have to be the same? No, as you can often buy channels and gratings separately. Should the loading classes be the same? Ideally, yes. The reason for this is that, in the intricate landscape of channel drain systems, the loading class isn't merely a solitary number but a dynamic interplay between different components.

Among these, the loading class of the grating emerges as a crucial element, one that significantly influences the loading class of the entire drainage system. The strength and integrity of the grating resonate with the loading class of the channel, crafting a harmonious relationship that determines the overall capacity and performance of the drainage system.

Consider a Class C Channel – it inherently boasts a load-bearing strength suited for specific applications. However, when it comes to selecting a grating, the relationship between the channel and grating loading class demands alignment. To maintain the integrity of the entire drainage system, the grating should be of at least a Class C rating. Placing a lower-rated grating, such as a Class B grating, onto a Class C Channel will lower the load rating of the entire system. This is because a channel drain is only as strong as its weakest component and adopts the loading class of the lowest-rated part. In the example of a class C250 channel and a B125 grating, the channel drain system would be classified as a B125 load rating overall.

Choosing the best Channel Drain for your project

The type of linear channel drainage that is best for any particular surface water drainage application will depend on a number of factors. As well as the loading requirements, you’ll also need to consider the following:

- The size and shape of the area to be drained - this will influence the size of your channel drain system, its layout, and number of components required.

- The expected volume of water - this will help you decided what type of grating you need, as you wouldn't want to use a low flow rate grating in an high flow rate area, etc.

- The budget - this will be key when it comes to deciding between budget and premium brands, and material choice for loading applications where there are multiple choices.

- The type of surface that the channels will be installed in - this can have implications on how easy certain types of channel drain are to install.

- The aesthetic requirements - if you need to maintain a certain aesthetic appeal, this could limit the grating options available or even require a bespoke option.

For more on these factors and our channel drain recommendations for the most common applications, check out the next article in our channel drain series, “Choosing the right channel drain for your project”.

Summary

Selecting the right linear channel drain as part of your wider water management and drainage system is an important choice. Choosing a channel drain aligned with your application's anticipated load demands will help ensure the durability, functionality, and safety of your drainage system, whether for use in a residential driveway or a heavy-duty industrial area.

However, the art of selecting optimal channel drainage materials involves balancing load-bearing capacity, cost-effectiveness, durability, aesthetics, and project requisites for efficient surface water management. Combining all of the knowledge in this article, and others in our channel drain series, will help you make an informed decision and enable you to choose the perfect channel drain system for your project.

And that’s it for our introductory guide to channel drains and their applications. Whether you're working on a construction project or landscape design, channel drainage can be a helpful addition. If, after reading up on all the information available, you decide this could indeed be the solution you need, check out our range of high-quality Linear Channel Drainage available to buy online.

Contact JDP today if you have any questions or need further advice about your channel drainage installation. Our team of experts are always on hand to help with all of your civils and drainage needs.