All underground pipework systems, including utilities and drainage, require the installation of access points for cleaning and maintenance purposes. They are especially crucial in drainage systems where blockages can occur, and play an important role in keeping domestic and commercial drains in good working order.

But just what is an inspection chamber? How often do they need to be installed along a pipeline? What options are available? These are all questions that we intend to answer in this article.

What is an Inspection Chamber?

An inspection chamber is one of the options available when it comes to installing access points, allowing drainages professionals to inspect, clean and repair underground pipework. They are often referred to as being “manholes”, but this is technically incorrect. While a manhole is also an access point, it permits the physical entrance of workers into underground systems (hence the name), whereas an inspection chamber only facilitates access for cameras and equipment.

Inspection chambers are best suited to installations where workers will only ever need access to carry out CCTV drain surveys, drain rodding and water jetting to inspect and clean the pipework without having to physically enter the chamber.

Terminology Tip: The terms “inspection chamber” and “manhole” or “man access inspection chamber” are often used interchangeably throughout the drainage industry, which can be confusing. The key thing to remember is that the minimum internal dimensions of a man access chamber are 600x900mm. Anything smaller than that is what we consider to be an inspection chamber and anything larger is a manhole chamber.

When and where are inspection chambers needed?

Inspection chambers are most useful when installed anytime there is a bend, intersection, or other significant change in the system. The more access points you have, the easier it will be to maintain the pipeline and clear any blockages that occur. Check out our guide on whether your house has the right drainage connections for more information.

How often do you need to install an inspection chamber?

Inspection chambers should ideally be installed along your pipeline in all of the following instances and as often as they occur:

- Where a branch pipe joins the system’s main run

- When there is a straight run of pipe that extends for more than 22 metres

- Where a pipe changes direction horizontally by more than 30 degrees

- When there is a change in the size of the pipe

Top Tip: Install an inspection chamber as often as is necessary to ensure that every part of the system can be reached by a drain rod. You’ll be grateful you did should a blockage ever occur.

Do I need a plastic or concrete inspection chamber?

This will largely depend on the application, the size of the chamber needed and whether you actually need a man access chamber instead.

For the type of access point discussed in this article (those that don’t require man access), plastic inspection chambers are becoming a more popular alternative to heavy, expensive concrete chambers. Here at JDP, we offer a range of plastic inspection chambers called AXEDO that are perfect for use in foul and surface water drainage systems. Find out if you have picked the right inspection chamber for your project.

If you are wanting a man access inspection chamber (one large enough for a person to fit in to) then a concrete manhole might be your best option.

What are the different parts of an inspection chamber?

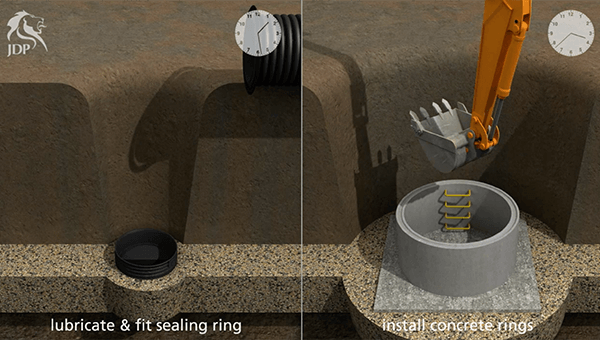

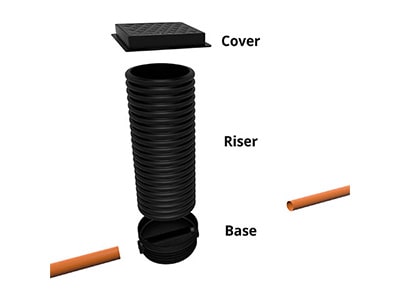

Inspection chambers typically come in three parts; a base, a riser and a cover. Depending on the manufacturer, they will either be supplied as a whole system, or with each sectional part sold separately so that you can buy exactly what you need. The risers sit on top of the base, with integral rubber seals in the joints, and the cover sits in a frame on top of the riser at ground level.

- Inspection Chamber Base

This is, unsurprisingly, the ‘bottom’ section of the chamber that sits closest to the drains. Most inspection chamber bases can be supplied with a number of inlets, that accept either 110mm or 160mm diameter pipes, to suit your project and/or blanking plugs to seal off the ones you don’t need.

- Inspection Chamber Riser

This is the mid-section of the chamber that sits on top of the base and is joined together by integral rubber seals. Available in a range of heights to suit, the riser is designed to connect the base that’s down with the drain pipes to the cover which sits at the surface. Most can be easily cut with a saw to get the exact height required for your installation.

- Inspection Chamber Cover

The cover of an inspection chamber (often called a manhole cover or access cover) is used to prevent unauthorised access to the chamber and for general safety purposes. They are available in a range of different sizes, materials and weight load classifications to suit all needs. Check out how to choose the right manhole cover for more information.

Is a Catchpit the same as an inspection chamber?

Well, yes and no...but mostly no. A catchpit (also known as a silt trap or interceptor trap) is an empty chamber installed along a drainage system. It is designed to catch silt and debris being carried along by the water and prevent it from building up in the pipeline where it could cause blockages. Catchpits are used in all wastewater management systems, including mainline sewers and stormwater drainage systems, and play a vital role in keeping that water flowing away from our properties.

Where an inspection chamber has its inlet and outlet pipes connected through its base section, a catchpit has its inlet and outlet pipes raised above the floor of the pit. This allows for water to flow into the pit and deposit any silt and debris it has picked up, which falls to the bottom, before it flows back out to continue along the drain.

Because this silt and debris will build up over time, it is vital that a catchpit is regularly cleaned out. For this reason, they still need to be accessible to workers via a suitable cover for inspection purposes. While this technically makes them a chamber that needs to be inspected, it does not make them an inspection chamber.

How deep should inspection chambers be installed?

This generally depends on the size of the inspection chamber, but the depth must always comply with building regulations - meaning there must be no risk to human life. As a rough guide:

- 300mm diameter chambers can generally go to a depth of 600mm

- 450mm diameter chambers can generally go to a depth of 1200mm

Any deeper and it either becomes near impossible to get a drain rod into the pipe to clear blockages, or the risk to human life is too high without a restricted access cover.

For more detailed information on installation depths check out this article.

Who is responsible for clearing blocked inspection chambers?

It is vitally important that inspection chambers and manhole chambers are well maintained and regularly cleaned. Failure to do so can result in damage to the chamber, blockages in the system and a significant health and safety risk to people. But who is responsible for doing so?

This depends on whether or not the inspection chamber in question is adoptable or non-adoptable. Water and sewage companies are generally recognised as being the most suitable people to own, operate and maintain all parts of a sewage network. This mean that if an inspection chamber serves two or more properties and connects to the UK public sewer system, it is likely to have been “adopted” by the relevant water and sewage company for the area. This makes it their responsibility to maintain, clean and unblock. Contact your water company if you think you have a blockage.

If, however, the inspection chamber serves just your property, then it will be your responsibility to have it maintained, regularly cleaned and unblocked if necessary.

SAFETY WARNING!

While you may be responsible for an inspection chamber on your property, you should never try to inspect it yourself. Inspection chambers and manholes can be dangerous due to being confined spaces that can contain toxic gasses. The inspection and cleaning of these chambers should ONLY be carried out by trained specialists with the right equipment.

How do you clean an inspection chamber you are responsible for?

By employing a qualified drain cleaning specialist, that’s how! We cannot stress the importance of this enough - DO NOT try to access or clean an inspection chamber yourself.

A specialist will have all the appropriate safety equipment and, most likely, use a mechanical cleaning machine that utilises high-pressure water and suction to get the job done.

If you spot any signs of there being a blockage in your drains, such water failing to drain away as quickly as normal or your inspection chamber overflowing, contact a local drain cleaning specialist as soon as you can.

Can you build over an inspection chamber?

In most cases, the short answer to this question is “No”, and the long answer is “No, please don’t!”. Inspection chambers and manhole chambers must always be easily accessible in order to serve their purpose as “access points”. This means that building over them isn’t a great idea.

If for some reason you need to build over an inspection chamber that is adopted, then it will be essential to check with the water and sewage company first. You may find your only options are to either have the chamber moved, the pipes diverted or change your building plans.

If the inspection chamber in your way is non-adoptable, we would still recommend speaking with a professional before starting any building work.

For more help and support regarding inspection chambers, contact the experts at JDP today. Our technical team is always available to help with all of your drainage needs.