Robust stormwater & sewer systems

JDP offer an extensive range of precast concrete flexible jointed pipes from 300mm to 2100mm including rocker pipes, bends, junctions and fittings. Suitable for storm water and sewer drainage applications with proven strength and durability.

Features & Benefits

- Proven 100 year service life

- Manufactured to European and British Standards

- Rigid pipe - structure not designed to deform

- Inherent strength and durability

- Minimal bedding requirement - less bedding material required and therefore less muck away off site

- Can be laid to depths of 8-12 metres

- Low reliance on site workmanship to achieve installed strength

- High resistance to water jetting

- Low risk of floatation in areas with high groundwater table

- Resistant to rodent attack

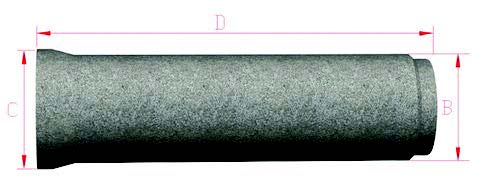

Standard Pipes

For storm water drainage or sewer drainage.

| Standard Sizes (mm) | 300 | 375 | 450 | 525 | 600 | 675 | 750 | 825 | 900 | 1050 | 1200 | 1350 | 1500 | 1800 | 2100 | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Internal Diameter (DN) | A | 300 | 375 | 450 | 525 | 600 | 675 | 750 | 805 | 900 | 1050 | 1200 | 1350 | 1500 | 1800 | 2100 |

| Barrel Diameter | B | 416 | 501 | 586 | 681 | 776 | 901 | 996 | 975 | 1080 | 1266 | 1460 | 1620 | 1790 | 2130 | 2460 |

| Socket Diameter | C | 497 | 575 | 665 | 760 | 852 | 960 | 1060 | 1130 | 1235 | 1420 | 1590 | 1800 | 2010 | 2380 | 2650 |

| Effective Length | D | 2500 | 2500 | 2500 | 2500 | 2500 | 2500 | 2500 | 2500 | 2500 | 2500 | 2500 | 2500 | 2500 | 2500 | 2500 |

| Approx. Weight (kg) | 449 | 590 | 729 | 974 | 1245 | 1818 | 2158 | 1691 | 2057 | 2756 | 3626 | 4416 | 5330 | 7302 | 9160 | |

Installation

Standards

BS EN1916: 2002 / BS5911-1: 2002.

- Correctly position and bed the first pipe. Prepare the bedding for the second pipe and hollow out for incoming spigot to prevent bedding material entering the joint.

- Ensure the joint ring is of the correct size and the spigot and socket are clean and undamaged.

- Ensure the joint ring is not twisted, is correctly located on the spigot and is the right way round.

- Lubricants must not be used where ‘G’ and Lamell rings are supplied. Lubrication is required with the ‘integral’ joint.

- Ensure the pipe to be jointed is adequately supported. The spigot should be centered carefully in the socket before jointing is completed, making sure bedding material does not enter the joint at any time.