MDPE, or Medium Density Polyethylene, is a versatile thermoplastic material widely used in various industries due to its durability, flexibility, and resistance to corrosion. No matter what size contract you are working on, MDPE will always be involved, whether it be an irrigation system, a house build, or even a hydro scheme.

MDPE is commonly used in the construction of piping systems for water supply, gas distribution, drainage, and irrigation as a replacement for traditional copper pipes, saving time and cost on installation. These pipes are available in a variety of colours, with each one signifying a specific application, so it’s important to know what products are on offer and where you can use them in your project.

This article delves into the different colours of MDPE pipes, their respective uses, and the advantages they offer. Unsure whether you should use PE80, PE100, MDPE, HPPE or HDPE? Check out our guide to polyethylene pressure pipe materials, which explains the differences between each material and where you should use them.

Why Do MDPE Pipes Come in Different Colours?

Different colours of MDPE pipes serve as a visual code to indicate their specific application. This colour-coding system helps make the construction and maintenance of piping systems more efficient and safer by enabling:

- Easy Identification: Different colours make it easier for installers and maintenance personnel to identify the purpose of each pipe.

- Compliance with Standards: Color-coding often adheres to industry standards and regulations, ensuring safety and efficiency.

- Prevention of Mistakes: Clear colour differentiation reduces the risk of accidental misconnections or incorrect installations.

The most common MDPE colours are Blue, Black, and Yellow, so let’s take a look at what each of them is used for.

Blue MDPE Pipes

Here is a quick look at the most frequently asked questions for Blue MDPE pipes.

What is Blue MDPE Pipe Used For?

Blue MDPE pipe is primarily used for below-ground cold water distribution systems to transport clean drinking (potable) water from the mains supply to homes and businesses under BS EN 12201 standards. The blue colour is a universal identifier for drinking water pipes, making it easy to distinguish from other types of piping.

What are the benefits of using Blue MDPE?

The primary benefit of using blue MDPE over traditional materials, such as copper pipes, is that it won’t corrode, making it ideal for delivering clean (potable) water services. It is also inert, so it has a good level of resistance to a wide range of naturally occurring ground chemicals, and doesn't support the microbiological growth of algae, bacteria, or fungi in normal operating conditions.

It's important to note that blue MDPE pipe is designed for cold water applications only. It is NOT suitable for hot water distribution, as high temperatures can affect the pipe's performance and durability.

What Sizes Do Blue MDPE Pipes Come In?

Blue MDPE pipes are available in a wide range of sizes to accommodate various applications. They typically come in coils of 25m, 50m, 100m, and 150m for ease of use. The most common sizes range from 20mm to 63mm in diameter. These sizes are suitable for both domestic and commercial installations, including smaller household plumbing systems and larger-scale water distribution networks.

Buy Blue MDPE Online

Black MDPE

Here is a quick look at the most frequently asked questions for Black MDPE pipes.

What is Black MDPE Pipe Used For?

Black MDPE pipe is primarily used for above-ground cold water distribution systems to transport clean drinking (potable) water in industrial and commercial settings under BS EN 12201 standards. It can also be used either above or below ground for industrial water supply systems and sewage pump mains systems where conformity to BS EN 12201:2003 standards is not required. Additionally, under EN 13244:2003 standards, Black MDPE can be suitable for:

- Industrial and commercial water supply: Transporting water to various points within a facility.

- Sewage and wastewater systems: Moving wastewater from buildings to treatment plants.

- Irrigation systems: Distributing water to agricultural fields.

- Hydroelectric power plants: Transporting water for power generation.

What are the benefits of using Black MDPE?

Black MDPE pipe is known for its durability, flexibility, and resistance to corrosion, making it a reliable choice for a variety of water distribution applications. Just like Blue MDPE, it is also resistant to a wide range of ground chemicals and is not prone to rot, corrosion, or stress cracking, making it suitable for above-ground conditions.

Black MDPE vs Black HDPE - what material is used?

The polyethylene material used to manufacture black MDPE is actually high-density polypropylene, meaning that, technically, the product is named black HDPE, but the market and industry still refer to this product as black MDPE. The change was made to improve the strength and durability of the pipes with tough PE100 material, making it suitable for use in both drinking and wastewater applications while still being compatible with push-fit compression fittings as well as electrofusion and butt fusion joining methods.

What Sizes Do Black MDPE Pipes Come In?

Black MDPE pipes are available in various sizes to accommodate different applications. They typically come in coils of 25m, 50m, 100m, and 150m for ease of use. The most common sizes range from 20mm to 63mm in diameter. These sizes are suitable for both domestic and commercial installations, including smaller household plumbing systems and larger-scale water distribution networks.

Black MDPE vs Blue MDPE - what's the difference?

While both Blue and Black MDPE pipes are made from the same material, they are primarily used for different applications in water supply systems:

- Black MDPE: Primarily used for above-ground cold water distribution systems, particularly in industrial and commercial settings. It can also be used for below-ground applications where the system doesn't need to comply with strict drinking water standards.

- Blue MDPE: Specifically designed for below-ground cold water distribution systems. It's ideal for transporting potable water from the mains supply to homes and businesses.

In essence, blue MDPE is typically used for domestic water supply, while black MDPE is more suited for industrial and commercial applications, including water supply, sewage, and irrigation.

Buy Black MDPE Online

Yellow MDPE

Here is a quick look at the most frequently asked questions for Yellow MDPE pipes.

What is Yellow MDPE Pipe Used For?

Yellow MDPE pipe is primarily used for below-ground gas distribution networks. It's suitable for both natural gas and LPG and is commonly used to connect properties to the main gas supply through a meter box.

What are the benefits of using Yellow MDPE?

The bright yellow colour is a universal identifier for gas pipes, making it easy to distinguish yellow gas MDPE from other types of piping. This colour coding helps to prevent accidental damage and ensures safety during installation and maintenance.

PE80 gas MDPE coils, which have a yellow outer colour and black inner colour, are often used for new pipelines, network rehabilitation, and pipe replacement. The black inner colour helps identify potential damage to the pipeline. These coils are typically approved to standards such as GIS/PL2-2 and BS EN 1555-2.

What Sizes Do Yellow MDPE Pipes Come In?

Yellow MDPE pipes typically come in 25mm and 32mm sizes, available in 50m or 100m coils. These sizes are suitable for most residential and commercial gas distribution applications.

In addition to these solid-colour MDPE pipe options, there are two important mixed-colour pipes available for special applications – Barrier Pipe and Industrial Water/Sewage Pump MDPE.

Buy Yellow MDPE Online

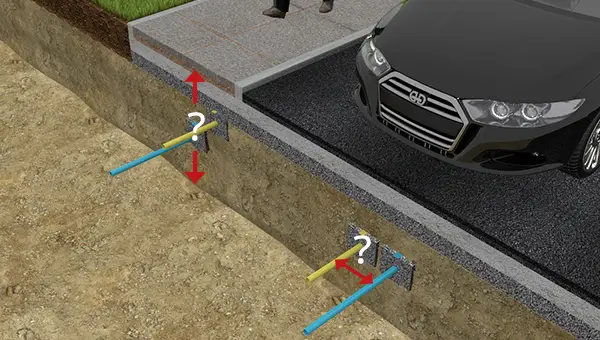

MDPE Barrier Pipe

Here is a quick look at the most frequently asked questions for MDPE Barrier pipes.

What is MDPE Barrier Pipe Used For?

MDPE Barrier Pipe is a specialised type of MDPE pipe that incorporates a multi-layer system to enhance its performance and durability. It typically consists of a black PE inner core, a protective aluminium layer, and a blue outer layer of PE with brown lines running along its length. This unique combination of layers is used to eliminate the migration of pollutants into drinking water.

When Should MDPE Barrier Pipe Be Used?

MDPE Barrier Pipe is particularly useful in situations where there is a risk of contamination from external sources. It is especially recommended for use in:

- Construction near industrial zones: Protects against potential pollutants from industrial activities.

- Agricultural areas: Reduces the risk of contamination from fertilisers and pesticides.

- Cemeteries: Minimises the risk of contamination from chemicals used in burial practices.

- Landfill sites: Prevents the migration of leachate (water that has percolated through a solid and leached out some components of the material) into water sources.

- Petrol stations: Protects against potential fuel spills and leaks.

- Military land: Reduces the risk of contamination from hazardous materials.

- Crossings at rivers: Protects against waterborne contaminants.

- Brownfield development sites: Mitigates the impact of past industrial activities.

- Areas prone to flooding: Reduces the risk of contamination from floodwaters.

By using MDPE Barrier Pipe in these situations, you can help to ensure the quality and safety of drinking water.

Industrial Water/Sewage Pump MDPE

Here is a quick look at the most frequently asked questions for Industrial Water/Sewage Pump MDPE pipes.

What is Industrial Water/Sewage Pump MDPE Used For?

Industrial Water/Sewage Pump MDPE is a specialised type of MDPE pipe designed to handle the higher pressures and demanding conditions associated with industrial water and sewage systems. These MDPE pipes are typically black with two orange lines running along their length, making them easily identifiable.

When Should Industrial Water/Sewage Pump MDPE Be Used?

Industrial Water/Sewage Pump MDPE can be used in applications where there are:

- High pressures: This type of MDPE is designed to withstand higher pressures than standard MDPE pipes, making it suitable for pumping applications where increased pressure is required to move water efficiently.

- Abrasive fluids: The specific formulation of the MDPE used in these pipes offers enhanced resistance to chemicals and other substances commonly encountered in industrial and sewage settings.

By using Industrial Water/Sewage Pump MDPE in these situations, you can help prolong the lifespan and maintain the structural integrity of your piping system.

And that’s it for this guide to the colours and uses of MDPE. We hope it has been informative and helpful, but do check out our other articles, MDPE Pressure Pipes – A Quick Guide, and Polyethylene Pressure Pipe Materials Explained, for further information. If you are in the market for reliable mains supply systems, we stock a great range of MDPE products for all applications in our Mains Supply section, which we'd recommend taking a look at.

If you have any other questions about MDPE pipes and their uses or need any further advice about mains supply systems in general, contact JDP today. Our team of experts are always on hand to help with all of your civils and drainage needs.