Have you ever seen those ridged corrugated plastic pipes waiting to be installed on a construction site? That would be Twinwall, a hidden hero of the water management world. In this guide, we will attempt to unlock the secrets of this versatile piping system, from types and uses to installation tips and how to choose the right products for your project. To begin with, we need first to understand what Twinwall is.

What is Twinwall Drainage?

Twinwall pipes are essentially two pipes welded together, one inside the other. The inner pipe, or wall, has a smooth surface to aid the flow of water, while the outer wall is ribbed (corrugated) to give it compressive strength and help protect the inner wall. Made from High-Density Polyethylene (HDPE), Twinwall pipes come in ridged lengths. They are known for their sturdiness and resistance to corrosion and chemicals, making them suitable for a diverse range of drainage needs.

What are the benefits of Twinwall Drainage Pipes?

The main benefits of Twinwall pipes are all centred around their versatility. Their impressive strength and wide range of sizes allow you to tackle projects from small gardens to heavy-duty roadways. Need to channel rainwater away from your flowerbeds? A smaller diameter pipe can handle that with ease. Need to run drainage under a road that can withstand constant traffic? Just choose a larger, more robust Twinwall pipe. The largest diameter Twinwall pipes can even be incorporated into flood management and attenuation systems, ensuring excess water is efficiently channelled away.

They may not always be the most economical choice for small projects, but the adaptability of Twinwall pipes makes them a strong contender for almost any drainage need. Here’s a quick breakdown of some of the key benefits you can expect from twinwall drainage pipes:

- Robust construction - Twinwall pipes can withstand heavy loads and pressure, making them ideal for areas with vehicular traffic or challenging soil conditions.

- Reliable performance - HDPE is resistant to temperature extremes, which ensures that twinwall pipes maintain consistent performance throughout the year, even in harsh weather conditions.

- Reduced risk of leaks or cracks - Their durable outer wall helps to minimise the risk of cracks or leaks that could compromise the drainage system's effectiveness.

- Lightweight Material - Despite their strength, Twinwall pipes are surprisingly light, making transportation and installation easier and safer than other alternatives.

- Smooth Flow - The inner surface of twinwall pipes is smooth, minimising friction and allowing water to flow freely through the system, reducing the chances of blockages.

What makes HDPE a good material choice for drainage pipes?

High-Density Polyethylene (HDPE) is a type of thermoplastic polymer. This means it is a type of plastic that can be softened and moulded when heated and hardens again when cooled. But what makes HDPE such a great choice?

- Strength Under Pressure - HDPE boasts an impressive strength-to-weight ratio. This translates to pipes that can handle significant loads without breaking or buckling, making them ideal for high-traffic areas and heavy-duty applications.

- Built to Last - Unlike some materials that degrade over time, HDPE is exceptionally resistant to corrosion and cracking. This ensures your drainage pipes will function flawlessly for years to come, minimising the need for replacements.

- Weather Resistant - HDPE is resistant to UV rays and harsh chemicals in the soil and can withstand a wide range of temperatures. This ensures reliable performance year-round.

- Lightweight Champion - Despite its impressive strength, HDPE is relatively lightweight (compared to other drainage pipe materials, such as concrete). This makes Twinwall pipes easier to transport and install, saving time and effort on your project.

- Sustainable Choice - HDPE is a recyclable material, making Twinwall pipes an eco-friendly option. This contributes to a more sustainable building process for environmentally conscious projects.

In short, HDPE offers the perfect blend of strength, durability, and lightweight functionality. These qualities make it a superior choice for Twinwall drainage pipes, ensuring a long-lasting and reliable drainage solution for your project.

Where can Twinwall Pipes be used?

Twinwall drainage pipes are suitable for a variety of drainage needs thanks to their strength and range of sizes. Here are some of their most common applications:

Garden and Patio Drainage

While perhaps not the most economical choice for garden use, Twinwall pipes do offer a powerful solution for targeted drainage. Their strength makes them ideal for channelling excess water away from patios, walkways, or clogged areas around your property. This helps prevent waterlogging, promotes healthy plant growth, and protects foundations from moisture damage.

Driveway Drainage

Driveways often take a beating from the elements, and Twinwall pipes are built to handle it. Their robust design means that they can withstand the weight of vehicles parked on the surface above them while still ensuring proper water drainage of the surrounding land, preventing puddles and potential damage caused by pooling water. This helps to keep your driveway safe and extends its lifespan.

Building and Construction Drainage

For projects with basements or foundations below the water table, Twinwall pipes are the perfect choice for channelling away groundwater. Their strength and durability help prevent moisture problems and ensure a stable foundation for your building. Additionally, twinwall pipes can be used to safeguard underground utilities, such as cables and pipelines, by acting as protective conduits.

Roads and Highways Drainage

High-traffic areas, like highways and roadways, are prime territory for Twinwall pipes. Their robust double-wall design can handle the constant wear and tear of vehicles driving overhead, ensuring proper water drainage and preventing road damage from water pooling or erosion. This keeps traffic flowing smoothly and reduces maintenance costs.

Agricultural Drainage

Keeping fields fertile requires proper drainage to prevent waterlogging and ensure healthy crops. Twinwall pipes are useful for channelling excess water away from agricultural land, promoting optimal soil conditions for root growth and preventing crop damage. Their larger size options make them ideal for large-scale drainage systems that manage high-volume water flow across expansive fields.

Beyond these common uses, Twinwall pipes can also be used to improve drainage for:

- Sports fields

- Retaining walls

- Golf courses

- And more

With their adaptability and diverse range of fittings and accessories, Twinwall pipes can be tailored to meet almost any drainage challenge.

What is the difference between Twinwall and Land Drainage pipes?

To those of us who are not well versed in the world of drainage, Twinwall and Land Drainage pipes can look the same. Indeed, they even both play a very similar role in channelling water away from areas where it isn’t wanted. However, their strengths and suitable applications do differ quite a bit. Let's take a quick look at their pros and cons to help you pick the right option for your project.

Twinwall Drainage Pipe

Pros: Twinwall pipes have a corrugated exterior and a smooth interior. They boast impressive strength due to this double-walled HDPE construction, making them ideal for heavy-duty applications like:

- High-traffic areas - Driveways, roads, and car parks.

- Deep excavations - Where pipes need to withstand significant external pressure.

- Flood management - Large-diameter pipes can handle substantial water volumes during heavy rain.

Cons: Their rigidity makes them less suitable for intricate layouts or tight spaces. Additionally, their heavier weight can increase installation costs for smaller projects.

Land Drainage Pipe.

Pros: Land Drainage pipes are typically made from single-walled HDPE, meaning they have a corrugated interior and exterior. This makes them more lightweight and flexible in design and allows for:

- Easy installation - They can navigate curves and bends more readily than Twinwall pipes.

- Cost-effective - Their lightweight nature makes them easier to transport and handle, reducing installation costs for smaller projects.

- Ideal for gardens and fields - Their flexibility is perfect for drainage systems in agricultural settings or landscaped areas.

Cons: Land Drainage pipes, due to their single-walled construction, cannot handle heavy loads or deep excavations. They are also typically available in smaller diameters, limiting their water flow capacity.

How to choose between Twinwall and Land Drainage

Knowing when it is best to use Twinwall and when it is best to use Land Drainage can sometimes be tricky. However, with an understanding of the differences mentioned above, we can break the choice down to the consideration of two factors:

- Project Needs - For heavy-duty applications or large water volumes, Twinwall reigns supreme. Land Drainage pipes excel in smaller projects and areas with intricate layouts.

- Budget - Land Drainage pipes are generally more cost-effective for smaller projects due to their lighter weight and easier installation.

By understanding these key distinctions, you can make an informed decision and ensure you choose the most suitable pipe for your drainage system.

How to choose the right type of Twinwall

Once you’ve decided to use Twinwall for your drainage project, you need to make two further choices: do you want perforated or unperforated pipes, and what diameter do you need? Here is what you need to know to help you answer these questions.

Perforated vs. Unperforated Pipes

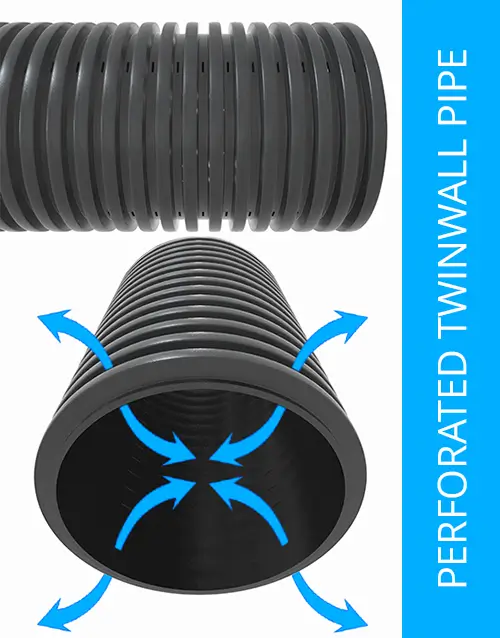

Twinwall pipes come in two main varieties: perforated and unperforated. Let’s take a look at the differences between them:

Perforated Twinwall Pipes.

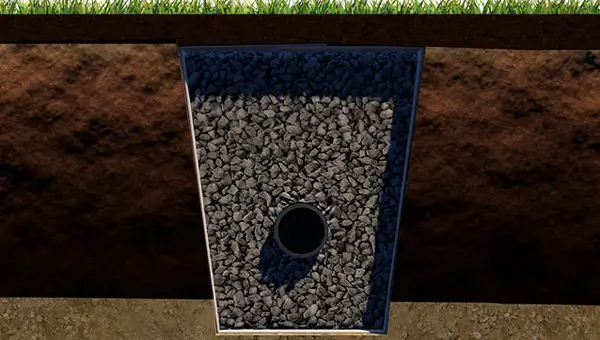

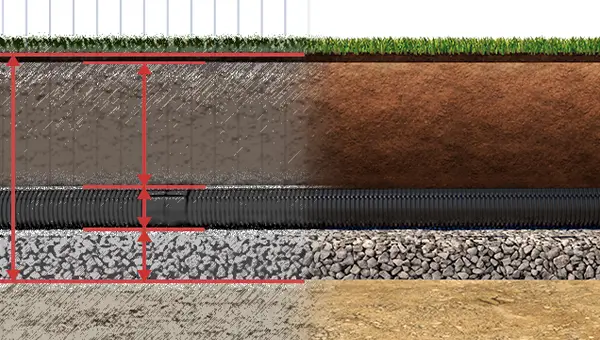

Perforated pipes have lots of tiny holes along their length, typically in the dwells between the corrugated ribs. These perforations allow water to seep in while the pipe channels it away to a designated collection point. They're ideal for situations where you need to collect water from the surrounding soil, such as:

- Land Drainage - Draining fields, gardens, or sports fields of excess water to prevent waterlogging.

- Foundation Drainage - Channelling groundwater away from building foundations to prevent moisture problems.

- Roadside Drainage - Collecting water from roadside ditches and preventing pooling on roadways.

Unperforated Twinwall Pipes.

Unperforated pipes have solid walls and are designed to transport water that has already been collected elsewhere. They're perfect for:

- Surface Drainage - Directing rainwater runoff from driveways, patios, or walkways away from structures.

- Underground Utility Protection - Encasing and protecting underground cables or pipelines from water damage.

- High-Volume Water Flow - Handling large volumes of water in applications like car parks or industrial areas.

It is vital that you choose the right type of twinwall pipe for your application. Therefore, if you have any doubts about which type is the most suitable for your needs, always consult a professional.

Choosing the Right Size Twinwall

Twinwall pipes come in a variety of diameters to suit a range of drainage applications. Here's a breakdown of the common sizes and their typical uses, along with more specific examples:

110mm Twinwall Pipes

110mm is the smallest diameter in the Twinwall family. While not suitable for large-scale projects, these pipes are perfect for small domestic uses.

- Applications: Suitable for targeted drainage in gardens:

- Draining flower beds or planters to prevent waterlogging and root damage.

- Directing water away from building foundations to reduce moisture issues.

- Creating shallow French drain systems for small, landscaped areas.

- Key Points:

- Not typically certified by BBA (British Board of Agrément).

- Not recommended for large-scale projects due to its limited flow capacity.

150mm Twinwall Pipes

While still one of the smallest diameters available, 150mm Twinwall pipes are a bit more versatile.

- Applications: Commonly used for drainage in small to medium-sized projects:

- Road and Driveway Drainage - Channelling rainwater runoff from driveways and paths to prevent flooding or erosion.

- Car Park Drainage - Creating drainage channels along the sides or centre of car parks to collect and direct surface water.

- Agricultural Drainage (Smaller Fields) - Installing sub-surface drainage systems in smaller fields to improve crop yields by removing excess water from the soil.

- Connecting to Larger Pipes - Used in conjunction with larger diameter pipes (225mm+) to channel water flow towards a designated discharge point in extensive drainage networks.

- Key Points:

- Often used in conjunction with road gullies to collect and transport rainwater runoff from roads and driveways.

- A versatile size suitable for various drainage needs due to its balance between capacity and ease of installation.

225mm Twinwall Pipes

This size bridges the gap between medium and larger applications. It's a good choice for draining moderate amounts of water.

- Applications: Primarily used in commercial applications:

- Large Car Park and Commercial Property Drainage - Managing water runoff from large car park surfaces or commercial building footprints.

- Drainage Systems for Industrial Areas - Collecting and directing rainwater runoff from industrial sites to prevent pooling and potential contamination issues.

- Drainage Around Major Highways - Used in some instances for highway shoulder drainage, particularly when high flow capacity is required.

- Collecting Rainwater from Medium-Sized Warehouse Roofs - Channelling rainwater runoff from medium-sized warehouse roofs to prevent overflow or structural strain.

- Key Points:

- Less commonly used for domestic garden drainage due to its larger size and capacity, which might be excessive for smaller areas.

- Suitable for mid-sized to large-scale commercial projects requiring significant flow capacity to handle higher volumes of water.

300mm Twinwall Pipes

Another mid-range diameter that offers a good balance between size and functionality.

- Applications: Primarily used in large-scale industrial applications:

- Drainage for Major Highways and Highway Shoulders - Essential for efficient drainage along major highways and roads, managing high volumes of water runoff from large traffic areas.

- Drainage Systems for Large Industrial Facilities - Collecting and directing industrial process water or rainwater runoff from expansive industrial sites.

- Collecting Rainwater from Very Large Warehouse Roofs - Channelling rainwater runoff from massive warehouse roofs to prevent overloading and potential roof damage.

- Creating Culverts (Large Diameter Pipes) - Used to create large-diameter passages under roads or driveways to allow water flow between connected areas.

- Key Points:

- Not typically used for domestic or small commercial applications due to its large size and capacity, which is suited for heavy-duty drainage needs.

- Ideal for large-scale projects requiring the highest flow capacity for efficient drainage of significant water volumes.

375mm Twinwall Pipes

This larger diameter Twinwall pipe is built for handling significant water volumes.

- Applications: Primarily used in large-scale highway drainage projects:

- Drainage Along Major Highways and Roads - Managing high volumes of water runoff along extensive highway and road networks, particularly for long stretches with significant traffic flow.

- Collecting Runoff from Large Road Networks - Collecting and channelling water runoff from large areas of paved surfaces to prevent flooding or infrastructure damage.

- Directing Water Flow Towards Larger Capacity Drainage Systems - As part of a comprehensive drainage network, directing collected water towards larger diameter pipes for final discharge.

- Key Points:

- Not typically used for domestic or small commercial applications due to its large size and capacity.

- Commonly used in conjunction with inspection chambers for system access and maintenance due to the increased pipe diameter and potential for complex drainage networks.

450mm Twinwall Pipes

Another large diameter pipe size ideal for projects handling large volumes of water.

- Applications: Similar to 375mm pipes, 450mm pipes are used in large-scale drainage projects, often for:

- Drainage Around Major Roads and Highways - Managing exceptionally high volumes of water runoff from extensive road networks, especially for highways with heavy traffic.

- Extensive Car Park Drainage Systems - Accommodating large areas of car parks by collecting and directing surface water runoff efficiently.

- Key Points:

- Suitable for high-volume water flow applications in large-scale projects.

- Requires careful planning and installation due to its larger size and weight.

- May be used in conjunction with inspection chambers for system access, especially in complex drainage networks.

600mm Twinwall Pipes

The heavy-duty workhorse of Twinwall pipes, the 600mm is built for the most challenging jobs.

- Applications: Exclusively used in large-scale civil engineering projects with exceptionally high flow requirements, such as:

- Drainage for Major Highways and Motorway Networks - Managing massive volumes of water runoff from vast motorway networks with multiple lanes and high traffic density.

- Drainage Systems for Large Airports - Directing water away from runways, taxiways, and airport surfaces to prevent flooding and ensure aircraft safety during landing and takeoff.

- Flood Control Systems - As part of extensive flood control systems, these pipes can handle large volumes of water during flood events to protect surrounding areas.

- Key Points:

- Least common size due to its significant size and capacity.

- Requires specialist handling equipment and expertise for installation due to its weight and dimensions.

- Plays a crucial role in large-scale infrastructure projects for efficient water management and flood mitigation.

At JDP, we also stock Large-Diameter Twinwall Pipes (750mm, 900mm, and 1050mm), which are primarily designed for use in stormwater management to help prevent localised flooding during heavy rainfall. An additional, and sometimes surprising, use for larger diameter twinwall pipes is as tunnels and play equipment in activity centres, sports fields, play parks, and even zoos and safari parks. Twinwall pipes really are that versatile.

The appropriate pipe diameter for your project will depend on several factors, such as:

- The volume of water you need to drain.

- The size of the area being drained.

- The type of application (e.g., garden drainage, road drainage).

For smaller domestic applications like gardens or driveways, 110mm or 150mm pipes might be sufficient. For larger commercial or industrial projects, larger diameter pipes (225mm or 300mm) are typically required to handle higher volumes of water flow. As the pipe diameter increases (375mm and above), applications become more specific to large-scale civil engineering projects with significant drainage requirements.

When in doubt, it's always recommended to consult with a drainage professional to determine the most suitable pipe diameter for your specific needs. They can assess your site conditions and water flow requirements to ensure optimal drainage system functionality.

Essential Twinwall Pipe Fittings

Twinwall pipes are just one component of a complete drainage system. To create a functional network, various fittings are used to connect pipes, change direction, and manage water flow. Here's an overview of some essential Twinwall pipe fittings:

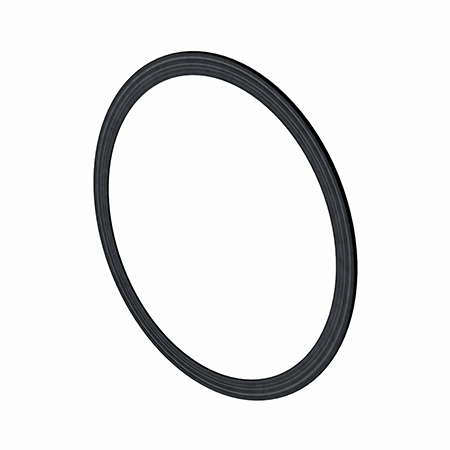

Twinwall Ring Seals

These create watertight connections between Twinwall pipes and fittings. They typically sit in the first dwell between the first and second corrugation from the end of the pipe before the fitting is connected over the top.

Twinwall Couplers

These fittings join two straight pipe sections together to create a continuous drainage line. They consist of a short length of pipe with a larger internal diameter at each end to accommodate the insertion of the pipe ends.

Twinwall Bends

These fittings allow for changes in direction within the drainage system. They are available in various angles, including:

- 15-degree Twinwall Bend - For minor directional adjustments.

- 30-degree Twinwall Bend - For creating gentle curves in the pipe run.

- 45-degree Twinwall Bend - For more pronounced directional changes.

- 90-degree Twinwall Bend - For right-angle turns in the pipework.

Twinwall T Junctions

These fittings connect three pipes, creating a branch line from the main drainage run. They are useful for incorporating additional drainage inlets into the system.

Twinwall Y Junctions

Similar to T Junctions, these fittings create a branch line but with a slightly angled connection point, often used for connecting sub-surface drains.

Twinwall Level Invert Reducer

This fitting connects pipes of different diameters while maintaining a consistent invert level (the lowest point within the pipe). This ensures proper water flow throughout the system.

Twinwall End Cap

These caps are used to seal off the open end of a Twinwall pipe, useful for terminating a drainage line or allowing for future connection points.

Twinwall Gate/Sluice Valve

These valves allow for manual control of water flow within the drainage system. They can be opened or closed to isolate sections of pipe for maintenance or cleaning.

Twinwall Flap Valve

These one-way valves allow water to flow freely in one direction but prevent backflow. They are useful in preventing flooding or unwanted water entry into specific areas of the drainage system.

Twinwall to Sewer Junctions

These specialised fittings connect Twinwall drainage pipes to existing sewer systems, ensuring proper discharge of collected water.

Twinwall to Sewer Reducers

Similar to level invert reducers, these connect Twinwall pipes to sewer systems but with a focus on adapting the pipe diameter for a secure and functional connection.

At JDP, our range of Twinwall fittings includes many high-quality fabricated ones that are manufactured in-house and are ideal for use in any non-BBA systems. You can learn more about our in-house products on our FabShop page.

By understanding the functions of the various Twinwall pipe fittings available, you can ensure a well-designed and efficient drainage system that meets your specific project requirements.

Are there any regulations that impact the use of Twinwall Drainage Pipes?

While there aren't specific regulations solely for Twinwall drainage pipes in the UK, there are regulations that indirectly impact their use. Here's a quick breakdown:

- Building Regulations Approved Document H - This document from the Department for Levelling Up, Housing and Communities (DLUHC) outlines the overall requirements for drainage systems in buildings. It emphasises proper drainage to prevent dampness, flooding, and health hazards. Twinwall drainage pipes can be used as long as they meet these performance requirements.

- British Standards (BS) - While not mandatory, some projects might reference relevant British Standards for drainage systems. Standards like BS EN 12056 provide specifications for plastic pipes for drainage and sewerage. Following these standards ensures the pipes meet the expected performance criteria.

- Highways Agency or National Roads Authority Requirements - These apply to drainage systems for major roads and highways. While they don't specify Twinwall pipes, they do outline minimum cover depths for drainage pipes depending on the traffic load. Twinwall pipes, with their strength, can be a suitable choice for meeting these requirements.

- Manufacturer's Recommendations - It's crucial to follow the specific installation guidelines provided by the manufacturer of the Twinwall pipes you're using. These recommendations will ensure proper installation for optimal performance and drainage effectiveness.

Please Note: Building Regulations Approved Document H, mentioned above, only covers England and Wales. For drainage regulations in Scotland, see Building Standards standard 3.6 and, for Northern Ireland, see Technical Booklet N - Drainage.

None of these regulations restrict the use of Twinwall drainage pipes, but they do provide a framework of requirements for drainage systems that your chosen Twinwall pipes may need to meet. If you are unsure about what standards your project will be relevant to your project, it's always best to consult with a drainage professional to ensure your installation will comply with best practices.

The other thing to be aware of with Twinwall is the BBA certification. We'll take a closer look at this next.

What is the BBA Certification?

The British Board of Agrément (BBA) is a respected organisation in the construction industry that issues certificates for construction products. A BBA certificate verifies that a product has been rigorously assessed against specific performance standards. This assessment typically involves product testing, factory production control checks, and ongoing monitoring.

Why is BBA Certification Important?

For specifiers, contractors, and building owners, BBA certification offers several key benefits:

- Assurance of Quality and Performance - A BBA certificate provides independent verification that a Twinwall pipe or a Twinwall fitting meets the claimed performance criteria, such as strength, durability, and hydraulic capacity. This helps ensure a reliable and long-lasting drainage system.

- Compliance with Building Regulations - In some cases, BBA certification can demonstrate compliance with relevant building regulations in the UK. This simplifies the approval process for construction projects.

- Peace of Mind - Specifying BBA-certified Twinwall pipes and fittings offers peace of mind, knowing the product has been independently assessed and meets the required standards.

When is a BBA Certification Important for Twinwall Pipe & Fittings?

A BBA certification is particularly important when selecting Twinwall pipes and fittings for critical drainage applications. Here are some scenarios where it's highly recommended:

- Large-scale projects - For extensive drainage systems in commercial, industrial, or infrastructure projects, using BBA-certified pipes ensures they can handle the expected water flow and environmental demands.

- High-risk applications - In situations where drainage failure could have significant consequences, such as near buildings or buried utility lines, BBA certification provides an extra layer of confidence in the pipe's performance.

- Meeting building regulations - If your project falls under specific building regulations requiring BBA-certified drainage products, choosing certified pipes ensures compliance and avoids potential delays.

- Project Specifications - Many construction projects may specify the use of BBA-certified Twinwall pipes to ensure quality and compliance with building regulations.

- Long-Term Performance - BBA certification often involves long-term testing and evaluation, providing greater confidence in the product's durability and ability to withstand harsh conditions throughout its expected lifespan.

When isn’t a BBA Certification Important for Twinwall Pipe & Fittings?

While BBA certification offers significant advantages, it's important to understand situations where it might not be the primary selection factor for Twinwall pipes. Here are some considerations:

- Non-Critical Drainage Applications - For less critical drainage applications, such as draining small garden beds or driveways, the structural requirements for the pipes might be less stringent. In these cases, using non-BBA-certified pipes with sufficient specifications for the intended load and water flow may be appropriate.

- Cost Considerations - BBA certification can increase the overall cost of Twinwall pipes. For smaller projects with tight budgets, non-BBA-certified pipes that meet the project's specific requirements can offer a more cost-effective solution.

- Project-Specific Engineering Assessments - For complex drainage projects, engineers may conduct their own thorough assessments of Twinwall pipe specifications and performance data. If a non-BBA-certified pipe meets or exceeds the project's engineering requirements, it might be deemed suitable for the application.

- Availability - In certain regions, BBA-certified Twinwall pipes might not be readily available. In such cases, using non-BBA-certified pipes with appropriate specifications and quality control procedures from reputable manufacturers can be a viable alternative.

Making an Informed Decision about BBA Twinwall

The decision of whether to use BBA-certified Twinwall pipes and fittings depends on various factors specific to each project. Here are some key questions to consider:

- Criticality of the Drainage Application - How crucial is the performance of the drainage system? For critical applications, BBA certification offers valuable assurance.

- Project Budget - Does the project budget prioritise cost-effectiveness, or is there a willingness to invest in the added confidence of BBA certification?

- Project Specifications - Do the project specifications explicitly require BBA-certified pipes?

- Engineer's Assessment - Will a qualified engineer be conducting a project-specific assessment of the Twinwall pipes?

The answer to these questions should tell you whether or not you need BBA-certified twinwall pipes.

It's important to remember that even without BBA certification, Twinwall pipes should still adhere to relevant British Standards (BS) or European Standards (EN) to ensure their quality and fitness for purpose. Therefore, a lack of certification doesn’t mean that non-BBA products are inherently inferior; it just means that they require a more informed evaluation from the buyer.

In summary, BBA certification remains a valuable benchmark for critical drainage projects or situations demanding guaranteed performance and regulatory compliance. However, for low-risk applications or budget-conscious projects, alternative non-BBA-certified pipes and fittings that meet the required standards can be a viable option.

If you are in any way unsure whether or not your system will require BBA-certified products, also seek professional advice. A qualified drainage professional can help assess your specific project requirements and advise on the most appropriate Twinwall pipe selection, considering factors like application, load requirements, and budget constraints.

And that’s it for our basic guide to Twinwall Drainage Pipes. Hopefully, this has given you a good grounding in the subject and answered some of the questions you might have had. If you are looking to dive in further, however, check out our other Twinwall articles for installation guidance and advice on things like maximum and minimum cover depths and where you can direct collected surface water.

If, on the other hand, you are already sold on the versatility of Twinwall and want to purchase some for your project, we have a wide range of Twinwall pipes and fittings available to buy online in our store.

Buy Twinwall Online

Should you have any further questions about using Twinwall for your project, contact us today. Our team of experts are always on hand to help with all of your civils and drainage needs.