It’s estimated that almost half a million tonnes of fats, oils and grease (known collectively as FOG) get washed into the UK sewage system each year. Just as they can clog up our arteries when eaten, fats, oils and grease rinsed away down our drains can clog up the pipes. Be it from cafes and restaurants or domestic kitchens, the problem of FOG in the sewers is a big one.

When fats, oils and grease collect in the sewers, they harden over time and form an almost concrete-like material that is hard to shift and leads to blockages. At a certain point, these blockages can result in soiled water from our toilets and wastewater from our sinks backing up and flooding our homes and businesses. In extreme cases, the blockages can clog up water treatment facilities and even end up polluting the environment too.

According to a blog post from Southern Water, more than 3,000 homes are flooded each year in the UK because of blockages caused by fats, oils and grease being washed into the sewers, and a staggering £90 million is spent on clearing these blockages across the country.

So, what can we do to help prevent these fatty issues? Well, the best way to avoid FOG build-ups is to avoid rinsing them down the sink. Scape all leftover food into the bin and let any fats, oils and grease produced during cooking cool and harden before scooping them into an empty tub or jar for safe disposal. Simple, right? Sadly, while we could all do this in our domestic kitchens (though many of us probably won’t), in commercial kitchens, this is often not a viable option due to the greater volume and frequency with which fats, oils and grease are produced.

This is where grease traps and separators can save the day.

What are Grease Traps?

Put simply, grease traps are an effective and hygienic method of separating fat, oil and grease from wastewater flow. They sit between your kitchen drains and the sewer system (be that mains or off-mains) to catch, trap or intercept (depending on your preferred terminology) FOG waste by slowing down the flow of water and allowing it to cool. This process causes the offending greasy materials to separate out and float to the top of the trap where they can then be safely removed.

They first came into use in the late 1800s and their design has hardly changed since. If it ain’t broke, and all that. However, there are a few different types that are worth noting as some are better suited than others to certain applications.

Before we get into how they all work, however, let’s first clear up the naming confusion that surrounds these products. You may know these FOG removal devices as grease traps, grease separators, grease interceptors, fat filters, fat catchers, or any other combination of words that mean the same thing. Ultimately, if it is a device that stops fats, oils and grease from entering the sewers, we’re probably talking about the same thing. The term “Grease Trap” is often used as a catch-all for such devices, but this can sometimes be misleading due to the way some manufacturers classify whether the device is for light or heavy use. For the sake of clarity throughout the rest of this article, here is how we classify these products.

- Grease Trap - a small FOG removal device used in applications where the volume and frequency of fats, oils, and grease being produced is fairly low. Typically installed below the sink in small restaurants, public houses & canteens. Also suitable for domestic use.

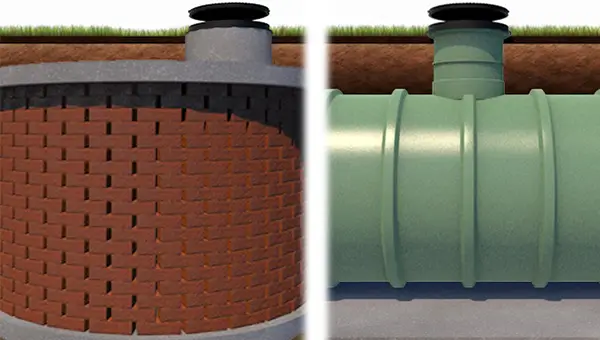

- Grease Separator - a large FOG removal device used in applications where the volume and frequency of fats, oils, and grease being produced is higher. Typically installed below ground for larger restaurants, hotels, and other commercial kitchens. The larger capacity of these tanks allows them to accommodate the higher flow rates and water pressures used in such applications.

Large or small, these devices tend to work the same way, so much of the information in this article will be relevant regardless of your application needs. However, unless we specifically need to make a distinction between the two, we’ll continue to use the generic “grease trap” naming convention to refer to them all…it’ll just save on the word count.

How do grease traps work?

As already mentioned, grease traps allow fats, oils and grease to naturally separate out from your kitchen wastewater in order for them to be removed prior to the water reaching the drainage system. They also allow any solids that have been washed down the sink to settle to the bottom of the trap, further reducing potential blockage material from the wastewater.

Important Note: A grease trap is not a food disposal unit and should not be treated as such. It will help catch small bits of food that get washed off plates, but too much solid material will only clog it up and prevent it from working properly. Unfinished food, thick gravy, sauces etc., should still be scrapped into the bin.

This is primarily achieved through the placement of baffles inside the unit that stop the water from passing straight through the drain pipes. The baffles effectively create three chambers within the tank:

- Inlet chamber - forces the wastewater down and slows its flow rate.

- Settlement chamber - allows the FOG, which are around 70-80% lighter than water, to rise up to the surface and any solids to settle to the bottom.

- Outlet chamber - collects the relatively de-greased water which is then pushed out into the normal sewage system as more wastewater is fed into the unit.

For smaller grease traps, the type you could install under a sink, vented flow control devices tend to be added to regulate the amount of wastewater coming into the unit while also mixing in air to help speed up the separation process. These are called “hydromechanical grease traps”. The larger underground units, sometimes called “passive” or “gravity” grease separators, can hold greater volumes of wastewater at any one time, which means they can rely solely on gravity to separate the FOG from the water.

The one drawback to any grease trap is its need to be emptied. It’s all well and good having a device that catches the fat, oil, and grease being washed down your sink, but if it isn’t cleaned out on a regular basis that FOG can cause a clog. With grease separators, you’ll probably get a month or two of use before needing to have the tank pumped, depending on its size and whether or not you add any biological grease treatment fluid into the system to help break down the FOG. Smaller units are likely to need emptying on a daily basis, but some do come with a waste receptacle built-in that enables an automatic removal feature to draw out a certain amount of FOG from the main unit and store it for later removal, thus extending the intervals between cleaning.

Please Note: While the smaller, under-sink type grease traps can be emptied by anyone (do consider at least wearing gloves though, as the stuff in them can be quite disgusting), underground grease separator tanks should always be cleaned by a professional, as the sludge and FOG will need to be pumped out and, since it will have sat in the tank for a longer period of time, can contain potentially harmful gases.

Where can grease traps be used?

Technically, grease traps can, and should, be used anywhere fats, oils and grease are produced and otherwise washed into the drains. For commercial and industrial kitchens, it is actually a legal requirement in the UK for them to have grease traps installed (see the Legislation section further down for more on this). Typically, this would include:

- Restaurants

- Pubs

- Cafe’s

- Bakeries

- Fast Food/Takeaways

- Food processing facilities

- Hotels

- Schools/ Colleges

- Hospitals

- and anywhere else that has a commercial/industrial kitchen

It should be fairly obvious, given the amount of food and waste such places produce on a daily basis, why these places would need grease traps, but what about domestic applications?

Are grease traps required in domestic waste systems?

Required? No. Recommended? Absolutely. While none of us will produce the same amount of fats, oils and grease as a restaurant in our own kitchens, we can still clog up our own drains by being careless of what we rinse away.

We all should know better than to rinse the gravy residue from our Sunday roast down the sink, but who has the time to leave fatty, oily, greasy dishes out long enough for the FOG to congeal and then scoop it all off into an empty butter tub to then have it sitting in the bin until collection day? Of course, the correct answer is that we all should…but the reality of life is that many of us don’t or just can’t be bothered. If you are one such person, then a small grease trap beneath your sink could help prevent you from being part of the problem without taking much extra effort on your part.

If you have an off-mains waste system (e.g. your wastewater goes into a sewage treatment plant or septic tank that drains into a soakaway), it is especially important to avoid washing fats, oils and grease down your kitchen sink. Grease, fats and cooking oils can all clog a septic soakaway by effectively 'waterproofing' it to the point where it becomes impossible for soil to absorb liquids. If this happens, you'll be needing a new soakaway to keep your system working properly.

Please Note: While you can get “small” grease traps for beneath a sink, the units themselves are still quite big (usually about the size of a large bread box) and will take up a good amount of space. If you have an off-mains sewage system that you are concerned about protecting and are short of space, a 500 litre grease separator buried between your kitchen waste pipe and your septic tank or sewage treatment plant might be a better solution.

In summary, installing grease traps can, by the removal of fat, oil and grease:

- Greatly reduced incidents of blocked drains from catering establishments

- Improve the performance of septic tanks and field drains

- Prevent contamination of small sewage treatment plants

Do you need a grease trap or a grease separator?

The answer to this all really depends on the application. If you want to keep fat, oil and grease out of your household drains, you probably won’t need a 2,000 litre grease separator buried in your back garden that can handle waste from 100 meals a day. More likely, you’ll be wanting a small grease trap that can fit under your sink.

But what if you are looking to manage the FOG removal for a commercial or industrial kitchen? This is where the choice can be a bit trickier. If you have a small cottage cafe selling tea, coffee, cakes and sandwiches, your main source of FOG waste will probably be from the sink or dishwasher you use to clean the cups and plates used throughout the day. For this sort of establishment, you could possibly get away with just having a small grease trap plumbed into the pipes for said appliances.

In larger restaurants and other foodservice kitchens, however, there will be a lot more fats, oils and grease produced from a lot more appliances such as:

- Sinks

- Dishwashers

- Combi ovens

- Rotisserie ovens

- Commercial woks

There will even be traces of FOG washed into the drains from the cleaning of kitchen surfaces and floors.

Important Note: You may be advised against connecting a dishwasher to a grease trap or separator due to the fact that the detergents and chemicals used in them can emulsify the FOG and therefore prevent the unit from working as intended. Double-check with your chosen manufacturer or supplier if this is the desired use for your trap or separator.

To handle the potential volume from multiple sources like this, the only real option is to have a larger separator installed underground to catch all the kitchen wastewater before it reaches the main drains.

| Grease Traps vs Grease Separators at a glance | ||

|---|---|---|

| Grease Trap | Grease Separator | |

| Size | Small Cylinder - Small Box | Large Box - Large Tank |

| Capacity | 35 - 200 litres | 400 - 45,000 litres |

| Water Pressure | Low | High |

| Installation | Above Ground | Below Ground |

| Cleaning Intervals | Every Day - Every Week | Every Few Weeks/Months |

How to choose the right size grease trap

Choosing the right size grease trap or separator for your needs is, arguably, the most important decision you need to make. Too small and it will be quickly overloaded, which would either render it ineffective at removing the FOG or potentially slow down the flow of water too much and cause it to back up through your pipes. Too large and the temptation to increase the time between cleaning intervals could lead to the food waste in the tank breaking down and releasing harmful gases and acids that can damage the unit.

So how do you decide what size grease trap or separator you need? Well, for most domestic situations, you are likely to only need either a 35 or 40 litre grease trap, unless you have a very large house with a kitchen that sees excessive use.

For commercial or industrial applications, however, it can be difficult to work out. Your main choices are to size by either:

- Capacity

- Maximum Flow

- Meals per Day

All larger grease traps and separators should be listed with one of these sizing specifications. There are ways to calculate your potential FOG removal needs for each one, but they are painfully complicated, requiring measuring the capacity of your appliances, average loads, and timing how long they take to drain to work out flow rates. Even if you manage to do all that, the results still only provide you with a ballpark estimate of the size you will need. Even the average meals per day measurement (which should be fairly easy to work out for your kitchen) can only give you a rough idea of the right size, because it is based on what each manufacturer decides to be a “standard meal”, and doesn't account for the extra fats, oils or grease that are likely to be present in fast food or fine cuisine kitchens.

Our advice here would be to either contact our technical team, speak to the manufacturer of your chosen tank, or consult with a professional installer to ensure you get the right product for your FOG removal needs.

What type of grease trap do you need?

While there are a few different types available, as mentioned earlier in the article, your choice between them is likely to be restricted by your FOG removal requirements. If your kitchen produces a lot of fats, oils and grease from multiple applications, then you are most likely to need a large underground grease separator. Since these tanks are almost always gravity systems (i.e. work by allowing the FOG to separate itself from the water over time), that will be the type you would need for most large restaurants and industrial kitchens.

If your FOG removal needs can be met by smaller grease traps connected to each appliance, you do then have more options available.

- Passive Grease Trap - this is your traditional, bog-standard, manual removal style trap. They are usually the cheapest type of grease trap, but they do require manual cleaning out on a very regular basis by whoever is working in your kitchen.

- Hydromechanical Grease Trap - this style is basically “Passive Plus”. It works on the same principle as a passive system, but it adds flow control and advanced FOG separation (via air admittance) to the system to help prolong the time between manual cleanings.

- Automatic Grease Trap - this style of trap is “Passive Pro”. It works the same way as a basic passive trap but adds in an automatic system that re-heats and then skims off the separated FOG layer into a storage container for easy removal. These traps are usually the most expensive of the three, but they are more efficient and require a less labour-intensive cleaning routine. The skimming schedule can be adjusted based on the amount of FOG produced, which means you don’t have to worry about manually measuring or checking the grease levels in the unit.

Ultimately, all three options will do the job and help you to keep fats, oils and grease out of the sewer system. The choice between them is really just cost vs convenience.

Where should grease traps be installed?

A grease trap or separator should be installed as close as possible to the source of contamination, before any foul waste can enter the drainage flow, while also taking the expected liquid temperature into consideration.

For small grease traps, the ideal location is beneath the sink or adjacent to the appliance. Keep in mind that you will need to have regular access to it, though, for cleaning purposes, so avoid installing it in difficult to reach areas.

For larger underground grease traps and separators, the ideal location is a little more complicated to advise on. It needs to be close to the source of contamination, far enough away to allow wastewater to cool, and needs to be accessible by a road tanker so that it can be professionally pumped out on a regular basis. Our experience indicates that units should be at least 12-15m away from the source of the contamination, as this distance is normally sufficient to allow cooling of most kitchen wastewaters when the discharge temperature is less than 60°C.

Important Note: Grease separators should not be installed beneath pavements or car parks. For further installation information, consult the manufacturer's guidance.

Grease Traps Legislation in the UK

There are currently (as of June 2022) no laws governing the control of fats, oils and grease in domestic drains. In other words, you don't Have to have a grease trap installed in your kitchen at home - unless it is used to produce food for commercial purposes.

It is, however, a legal requirement for any and all businesses that produce hot food commercially to properly manage their food waste. In other words, any kitchen that produces fats, oils and grease from the food they make must have a suitable grease trap or separator installed, and properly maintained, by law.

The legislation that covers this issue is actually quite extensive and includes:

- Building Regulations - Document H, section 2.21 states that any commercial food premises serving hot food that is connected to the mains drainage system must be fitted with a suitable grease trap or separator.

- The Building Act 1984 - Section 59 states that local authorities have the power to require satisfactory drainage from buildings, which means installation of a FOG removal system can be enforced.

- Environmental Protection Act 1990 - all businesses have a duty of care to ensure that all waste is disposed of in accordance with section 34. Failure to comply with local authority directives regarding disposal of waste can result in prosecution under section 80 of the act.

- Food Safety Act 1990 - any build-up or blockage caused by fats, oils and grease is considered to be a failure to comply with food hygiene regulations that can have severe consequences.

- The Water Industry Act 1991 - the permittance of any matter into the drainage system that can impede the natural flow of wastewater is considered a criminal offence.

In short…if you have a food business, install a grease trap or separator and save yourself a whole mess of headaches.

However, the regulations don’t just stop at making you install one, they also control what you can buy and how the waste can be disposed of. All grease traps in the UK must be designed in accordance with BS EN 1824-2:2002 standards and comply with BS EN 1825-1:2004 regulations. Further than that, the Animal By-Products Regulations EC 1774/2002 state that all cleaning and disposal of oils, fats and grease must be carried out by a licensed waste carrier.

It is also important to keep detailed records of your maintenance schedule onsite too, since you will need to have them available for inspection as and when required by the various regulatory authorities.

Non-compliance with any of the above can result in pretty hefty fines and, should you be caught out repeatedly, even the forced closure of your business. Face the fats, don't let oil be your foil and make peace with your grease by installing a trap or separator to help keep the drains FOG and clog-free.

And that’s it for our basic guide to grease traps and separators. If, after reading up on all the information available, you decide that such a device could indeed be the solution you need, we supply an extensive range of Grease Separators suitable for small restaurants, public houses & canteens, as well as larger restaurants, hotels, and other commercial kitchens.

Should you have any questions or need any further advice about grease traps, though, contact JDP today. Our team of experts are always on hand to help with all of your civils and drainage needs.